Page 91 - Pipeline Rules of Thumb Handbook

P. 91

78 Pipeline Rules of Thumb Handbook

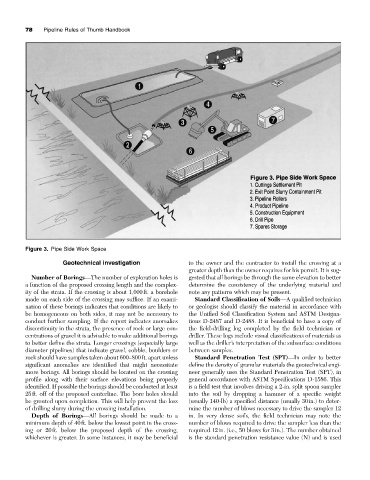

Figure 3. Pipe Side Work Space

Geotechnical investigation to the owner and the contractor to install the crossing at a

greater depth than the owner requires for his permit. It is sug-

Number of Borings—The number of exploration holes is gested that all borings be through the same elevation to better

a function of the proposed crossing length and the complex- determine the consistency of the underlying material and

ity of the strata. If the crossing is about 1,000ft. a borehole note any patterns which may be present.

made on each side of the crossing may suffice. If an exami- Standard Classification of Soils—A qualified technician

nation of these borings indicates that conditions are likely to or geologist should classify the material in accordance with

be homogeneous on both sides, it may not be necessary to the Unified Soil Classification System and ASTM Designa-

conduct further sampling. If the report indicates anomalies tions D-2487 and D-2488. It is beneficial to have a copy of

discontinuity in the strata, the presence of rock or large con- the field-drilling log completed by the field technician or

centrations of gravel it is advisable to make additional borings driller. These logs include visual classifications of materials as

to better define the strata. Longer crossings (especially large well as the driller’s interpretation of the subsurface conditions

diameter pipelines) that indicate gravel, cobble, boulders or between samples.

rock should have samples taken about 600–800ft. apart unless Standard Penetration Test (SPT)—In order to better

significant anomalies are identified that might necessitate define the density of granular materials the geotechnical engi-

more borings. All borings should be located on the crossing neer generally uses the Standard Penetration Test (SPT), in

profile along with their surface elevations being properly general accordance with ASTM Specifications D-1586. This

identified. If possible the borings should be conducted at least is a field test that involves driving a 2-in. split spoon sampler

25ft. off of the proposed centerline. The bore holes should into the soil by dropping a hammer of a specific weight

be grouted upon completion. This will help prevent the loss (usually 140-lb) a specified distance (usually 30in.) to deter-

of drilling slurry during the crossing installation. mine the number of blows necessary to drive the sampler 12

Depth of Borings—All borings should be made to a in. In very dense soils, the field technician may note the

minimum depth of 40ft. below the lowest point in the cross- number of blows required to drive the sampler less than the

ing or 20ft. below the proposed depth of the crossing, required 12in. (i.e., 50 blows for 3in.). The number obtained

whichever is greater. In some instances, it may be beneficial is the standard penetration resistance value (N) and is used