Page 467 - Pipelines and Risers

P. 467

434 Chapter 23

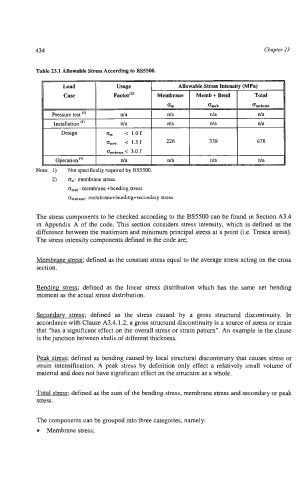

Table 23.1 Allowable Stress According to BS5500.

I :: I Factor"' Allowable Stress Intensity (MPa)

Usage

Total

Pressure test (I) I n/a

Installation (I) I n/a

Design

om* < 1.5 f

Note: 1) Not specifically required by BS5500.

2) om- membrane stress

oM - membrane +bending stress

membrane+bending+secondary stress

~ ~ m + b + ~ ~ -

The stress components to be checked according to the BS5500 can be found in Section A3.4

in Appendix A of the code. This section considers stress intensity, which is defined as the

difference between the maximum and minimum principal stress at a point (Le. Tresca stress).

The stress intensity components defined in the code are;

Membrane stress; defined as the constant stress equal to the average stress acting on the cross

section.

Bending stress; defined as the linear stress distribution which has the same net bending

moment as the actual stress distribution.

Secondarv stress; defined as the stress caused by a gross structural discontinuity. In

accordance with Clause A3.4.1.2, a gross structural discontinuity is a source of stress or strain

that "has a significant effect on the overall stress or strain pattern". An example in the clause

is the junction between shells of different thickness.

Peak stress; defined as bending caused by local structural discontinuity that causes stress or

strain intensification. A peak stress by definition only effect a relatively small volume of

material and does not have significant effect on the structure as a whole.

Total stress; defined as the sum of the bending stress, membrane stress and secondary or peak

stress.

The components can be grouped into three categories, namely:

Membrane stress;