Page 517 - Pipelines and Risers

P. 517

484 Chapter 25

Ph= Probability of failure in yearn

In this calculation example the inflation rate used is 2% and the "interest rate" used is 6%.

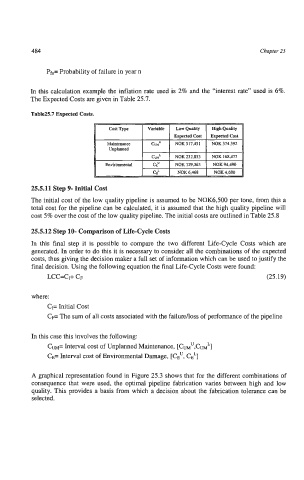

The Expected Costs are given in Table 25.7.

Table25.7 Expected Costs.

Envimental I &" I NOK129.363 I NOK94.490 [

25.5.11 Step 9- Initial Cost

The initial cost of the low quality pipeline is assumed to be NOK6,500 per tone, from this a

total cost for the pipeline can be calculated, it is assumed that the high quality pipeline will

cost 5% over the cost of the low quality pipeline. The initial costs are outlined in Table 25.8

25.5.12 Step 10- Comparison of Life-Cycle Costs

In this final step it is possible to compare the two different Life-Cycle Costs which are

generated. In order to do this it is necessary to consider all the combinations of the expected

costs, thus giving the decision maker a full set of information which can be used to justify the

final decision. Using the following equation the final Life-Cycle Costs were found:

LCC=C,+ CF (25.19)

where:

CI= Initial Cost

CF The sum of all costs associated with the failureAoss of performance of the pipeline

In this case this involves the following:

CUM= Interval cost of Unplanned Maintenance, [C~hn",Cm~]

CE= Interval cost of Environmental Damage, [CE", CE"]

A graphical representation found in Figure 25.3 shows that for the different combinations of

consequence that were used, the optimal pipeline fabrication varies between high and low

quality. This provides a basis from which a decision about the fabrication tolerance can be

selected.