Page 44 - Piston Engine-Based Power Plants

P. 44

36 Piston Engine-Based Power Plants

Compressing a gas raises its temperature and the compression ratio

will affect the propensity of the air fuel mixture to ignite spontane-

ously and so must be carefully controlled. The likelihood of this can

also change with engine load and speed.

Efficiency and power output have traditionally been the key consid-

erations in engine design. Today emissions are also an important but con-

trary consideration; optimising an engine for low emissions can lead to

lower efficiency or lower engine power, so finding a compromise that bal-

ances the different demands is a vital part of modern engine engineering.

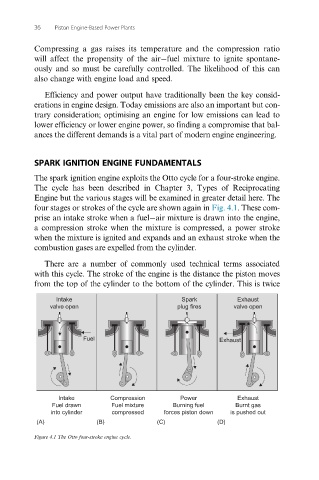

SPARK IGNITION ENGINE FUNDAMENTALS

The spark ignition engine exploits the Otto cycle for a four-stroke engine.

The cycle has been described in Chapter 3, Types of Reciprocating

Engine but the various stages will be examined in greater detail here. The

four stages or strokes of the cycle are shown again in Fig. 4.1.These com-

prise an intake stroke when a fuel air mixture is drawn into the engine,

a compression stroke when the mixture is compressed, a power stroke

when the mixture is ignited and expands and an exhaust stroke when the

combustion gases are expelled from the cylinder.

There are a number of commonly used technical terms associated

with this cycle. The stroke of the engine is the distance the piston moves

from the top of the cylinder to the bottom of the cylinder. This is twice

Intake Spark Exhaust

valve open plug fires valve open

Fuel Exhaust

Intake Compression Power Exhaust

Fuel drawn Fuel mixture Burning fuel Burnt gas

into cylinder compressed forces piston down is pushed out

(A) (B) (C) (D)

Figure 4.1 The Otto four-stroke engine cycle.