Page 273 - Plastics Engineering

P. 273

256 Processing of Plastics

D

Pitch =n tan 0

, e ~

r

KD

\ \ 'WA\\

AIPI

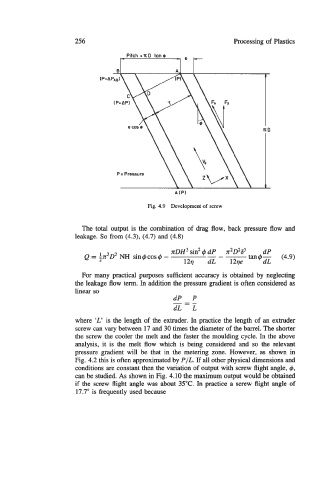

Fig. 4.9 Development of screw

The total output is the combination of drag flow, back pressure flow and

leakage. So from (4.3), (4.7) and (4.8)

nDH3 sin2 I$ dP n2D2J3 dP

Q = $T~D~ sin4cos4 - tan+-- (4.9)

NH

12~ dL 12~e dL

For many practical purposes sufficient accuracy is obtained by neglecting

the leakage flow term. In addition the pressure gradient is often considered as

linear so

dP P

-

_- -

dL L

where 'L' is the length of the extruder. In practice the length of an extruder

screw can vary between 17 and 30 times the diameter of the barrel. The shorter

the screw the cooler the melt and the faster the moulding cycle. In the above

analysis, it is the melt flow which is being considered and so the relevant

pressure gradient will be that in the metering zone. However, as shown in

Fig. 4.2 this is often approximated by P/L. If all other physical dimensions and

conditions are constant then the variation of output with screw flight angle, 4,

can be studied. As shown in Fig. 4.10 the maximum output would be obtained

if the screw flight angle was about 35°C. In practice a screw flight angle of

17.7" is frequently used because