Page 277 - Plastics Engineering

P. 277

260 Processing of Plastics

1

0.9

0.8

U

-- 0.7

c

Q)

I

0

E 0.6

8

g 0.5

E

0.4

0.3

0.2

0 0.2 0.4 0.6 0.8

Aspect ratio (db)

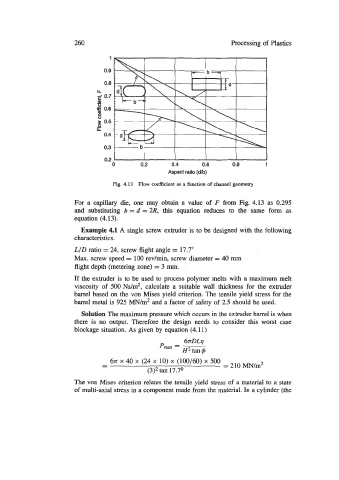

Fig. 4.13 Flow coefficient as a function of channel geometry

For a capillary die, one may obtain a value of F from Fig. 4.13 as 0.295

and substituting b=d= 2R, this equation reduces to the same form as

equation (4.13).

Example 4.1 A single screw extruder is to be designed with the following

characteris tics.

L/D ratio = 24, screw flight angle = 17.7"

Max. screw speed = 100 rev/min, screw diameter = 40 mm

flight depth (metering zone) = 3 mm.

If the extruder is to be used to process polymer melts with a maximum melt

viscosity of 500 Ns/m2, calculate a suitable wall thickness for the extruder

barrel based on the von Mises yield criterion. The tensile yield stress for the

barrel metal is 925 MN/m2 and a factor of safety of 2.5 should be used.

Solution The maximum pressure which occurs in the extruder barrel is when

there is no output. Therefore the design needs to consider this worst case

blockage situation. As given by equation (4.1 1)

6nDLr)

P,, = -

H2 tan #J

6~ x 40 x (24 x 10) x (100/60) x 500

- = 210 m/m2

-

(3)2 tan 17.7O

The von Mises criterion relates the tensile yield stress of a material to a state

of multi-axial stress in a component made from the material. In a cylinder (the