Page 281 - Plastics Engineering

P. 281

264 Processing of Plastics

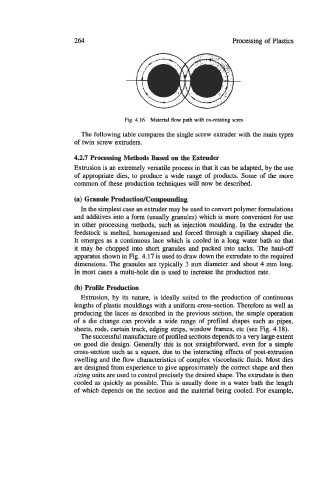

Fig. 4.16 Material flow path with co-rotating scres

The following table compares the single screw extruder with the main types

of twin screw extruders.

4.2.7 Processing Methods Based on the Extruder

Extrusion is an extremely versatile process in that it can be adapted, by the use

of appropriate dies, to produce a wide range of products. Some of the more

common of these production techniques will now be described.

(a) Granule ProductiodCompounding

In the simplest case an extruder may be used to convert polymer formulations

and additives into a form (usually granules) which is more convenient for use

in other processing methods, such as injection moulding. In the extruder the

feedstock is melted, homogenised and forced through a capillary shaped die.

It emerges as a continuous lace which is cooled in a long water bath so that

it may be chopped into short granules and packed into sacks. The haul-off

apparatus shown in Fig. 4.17 is used to draw down the extrudate to the required

dimensions. The granules are typically 3 mm diameter and about 4 mm long.

In most cases a multi-hole die is used to increase the production rate.

(b) Profile Production

Extrusion, by its nature, is ideally suited to the production of continuous

lengths of plastic mouldings with a uniform cross-section. Therefore as well as

producing the laces as described in the previous section, the simple operation

of a die change can provide a wide range of profiled shapes such as pipes,

sheets, rods, curtain track, edging stsips, window frames, etc (see Fig. 4.18).

The successful manufacture of profiled sections depends to a very large extent

on good die design. Generally this is not straightforward, even for a simple

cross-section such as a square, due to the interacting effects of post-extrusion

swelling and the flow characteristics of complex viscoelastic fluids. Most dies

are designed from experience to give approximately the correct shape and then

sizing units are used to control precisely the desired shape. The extrudate is then

cooled as quickly as possible. This is usually done in a water bath the length

of which depends on the section and the material being cooled. For example,