Page 285 - Plastics Engineering

P. 285

268 Processing of Plastics

This example illustrates the simplified approach to film blowing. Unfortu-

nately in practice the situation is more complex in that the film thickness is

influenced by draw-down, relaxation of induced stresses/strains and melt flow

phenomena such as die swell. In fact the situation is similar to that described

for blow moulding (see below) and the type of analysis outlined in that section

could be used to allow for the effects of die swell. However, since the most

practical problems in film blowing require iterative type solutions involving

melt flow characteristics, volume flow rates, swell ratios, etc the study of these

is delayed until Chapter 5 where a more rigorous approach to polymer flow

has been adopted.

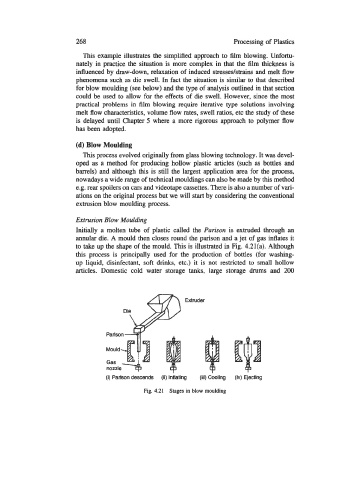

(d) Blow Moulding

This process evolved originally from glass blowing technology. It was devel-

oped as a method for producing hollow plastic articles (such as bottles and

barrels) and although this is still the largest application area for the process,

nowadays a wide range of technical mouldings can also be made by this method

e.g. rear spoilers on cars and videotape cassettes. There is also a number of vari-

ations on the original process but we will start by considering the conventional

extrusion blow moulding process.

Extrusion Blow Moulding

Initially a molten tube of plastic called the Parison is extruded through an

annular die. A mould then closes round the parison and a jet of gas inflates it

to take up the shape of the mould. This is illustrated in Fig. 4.21(a). Although

this process is principally used for the production of bottles (for washing-

up liquid, disinfectant, soft drinks, etc.) it is not restricted to small hollow

articles. Domestic cold water storage tanks, large storage drums and 200

Extruder

(i) Parison descends (ii) Inflating (iii) Cooling (iv) Ejecting

Fig. 4.21 Stages in blow moulding