Page 290 - Plastics Engineering

P. 290

Processing of Plastics 273

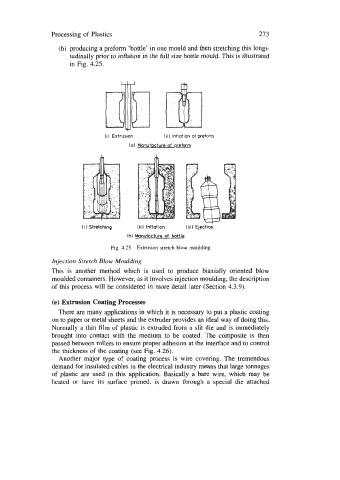

(b) producing a preform ‘bottle’ in one mould and then stretching this longi-

tudinally prior to inflation in the full size bottle mould. This is illustrated

in Fig. 4.25.

(11 Extruscon (111 Inflation of preform

la) Manufacture of prefwm

(I ) Stretching (ii) Inflation (iiil Ejection

Ib) Manufacture of bottle

Fig. 4.25 Extrusion stretch blow moulding

Injection Stretch Blow Moulding

This is another method which is used to produce biaxially oriented blow

moulded containers. However, as it involves injection moulding, the description

of this process will be considered in more detail later (Section 4.3.9).

(e) Extrusion Coating Processes

There are many applications in which it is necessary to put a plastic coating

on to paper or metal sheets and the extruder provides an ideal way of doing this.

Normally a thin film of plastic is extruded from a slit die and is immediately

brought into contact with the medium to be coated. The composite is then

passed between rollers to ensure proper adhesion at the interface and to control

the thickness of the coating (see Fig. 4.26).

Another major type of coating process is wire covering. The tremendous

demand for insulated cables in the electrical industry means that large tonnages

of plastic are used in this application. Basically a bare wire, which may be

heated or have its surface primed, is drawn through a special die attached