Page 291 - Plastics Engineering

P. 291

274 Processing of Plastics

(driven) Coated

fabric

Fig. 4.26 Extrusion coating process

be coated

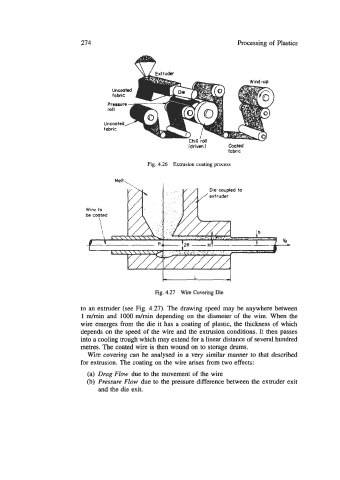

Fig. 4.27 Wire Covering Die

to an extruder (see Fig. 4.27). The drawing speed may be anywhere between

1 dmin and lo00 dmin depending on the diameter of the wire. When the

wire emerges from the die it has a coating of plastic, the thickness of which

depends on the speed of the wire and the extrusion conditions. It then passes

into a cooling trough which may extend for a linear distance of several hundred

metres. The coated wire is then wound on to storage drums.

Wire covering can be analysed in a very similar manner to that described

for extrusion. The coating on the wire arises from two effects:

(a) Drug Flow due to the movement of the wire

(b) Pressure Flow due to the pressure difference between the extruder exit

and the die exit.