Page 295 - Plastics Engineering

P. 295

278 Processing of Plastics

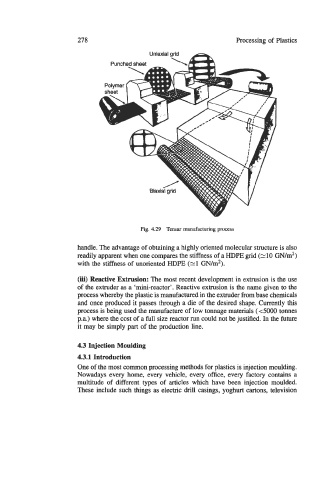

Fig. 4.29 Tensar manufacturing process

handle. The advantage of obtaining a highly oriented molecular structure is also

readily apparent when one compares the stiffness of a HDPE grid (-10 GN/m2)

with the stiffness of unoriented HDPE (21 GN/m2).

(iii) Reactive Extrusion: The most recent development in extrusion is the use

of the extruder as a ‘mini-reactor’. Reactive extrusion is the name given to the

process whereby the plastic is manufactured in the extruder from base chemicals

and once produced it passes through a die of the desired shape. Currently this

process is being used the manufacture of low tonnage materials (4000 tonnes

p.a.) where the cost of a full size reactor run could not be justified. In the future

it may be simply part of the production line.

4.3 Injection Moulding

4.3.1 Introduction

One of the most common processing methods for plastics is injection moulding.

Nowadays every home, every vehicle, every office, every factory contains a

multitude of different types of articles which have been injection moulded.

These include such things as electric drill casings, yoghurt cartons, television