Page 299 - Plastics Engineering

P. 299

282 Processing of Plastics

to inject melt into the mould. A typical injection moulding machine cycle is

illustrated in Fig. 4.31. It involves the following stages:

(a) After the mould closes, the screw (not rotating) pushes forward to inject

melt into the cooled mould. The air inside the mould will be pushed out

through small vents at the furthest extremities of the melt flow path.

(b) When the cavity is filled, the screw continues to push forward to apply

a holding pressure (see Fig. 4.31). This has the effect of squeezing extra

melt into the cavity to compensate for the shrinkage of the plastic as

it cools. This holding pressure is only effective as long as the gate@)

remain open.

(c) Once the gate@) freeze, no more melt can enter the mould and so the

screw-back commences. At this stage the screw starts to rotate and draw

in new plastic from the hopper. This is conveyed to the front of the

screw but as the mould cavity is filled with plastic, the effect is to push

the screw backwards. This prepares the next shot by accumulating the

desired amount of plastic in front of the screw. At a pre-set point in time,

the screw stops rotating and the machine sits waiting for the solidification

of the moulding and runner system to be completed.

(d) When the moulding has cooled to a temperature where it is solid enough

to retain its shape, the mould opens and the moulding is ejected. The

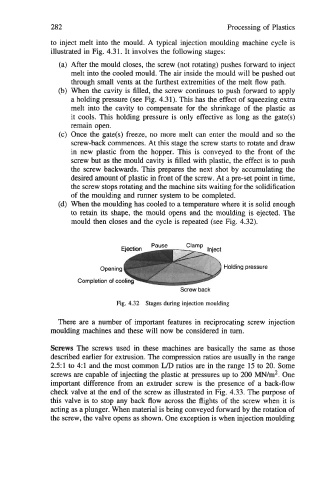

mould then closes and the cycle is repeated (see Fig. 4.32).

Holding pressure

Screw back

Fig. 4.32 Stages during injection moulding

There are a number of important features in reciprocating screw injection

moulding machines and these will now be considered in turn.

Screws The screws used in these machines are basically the same as those

described earlier for extrusion. The compression ratios are usually in the range

251 to 4:l and the most common UD ratios are in the range 15 to 20. Some

screws are capable of injecting the plastic at pressures up to 200 MN/m*. One

important difference from an extruder screw is the presence of a back-flow

check valve at the end of the screw as illustrated in Fig. 4.33. The purpose of

this valve is to stop any back flow across the flights of the screw when it is

acting as a plunger. When material is being conveyed forward by the rotation of

the screw, the valve opens as shown. One exception is when injection moulding