Page 298 - Plastics Engineering

P. 298

Processing of Plastics 28 1

However, nowadays this type of machine is seldom used because it is

considerably more complicated and more expensive than necessary. One area

of application where it is still in use is for large mouldings because a large

volume of plastic can be plasticised prior to injection using the primary cylinder

plunger.

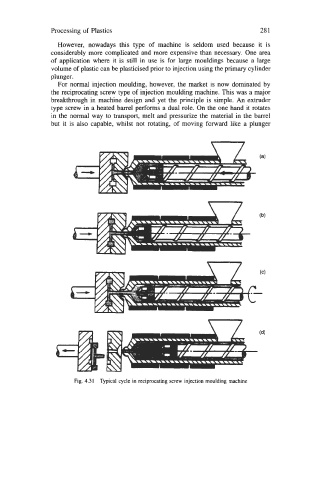

For normal injection moulding, however, the market is now dominated by

the reciprocating screw type of injection moulding machine. This was a major

breakthrough in machine design and yet the principle is simple. An extruder

type screw in a heated barrel performs a dual role. On the one hand it rotates

in the normal way to transport, melt and pressurize the material in the barrel

but it is also capable, whilst not rotating, of moving forward like a plunger

-

Fig. 4.31 Spica1 cycle in reciprocating screw injection moulding machine