Page 297 - Plastics Engineering

P. 297

280 Processing of Plastics

Material hopper

Electrical

Electrical

Feed adjustment

material plunger

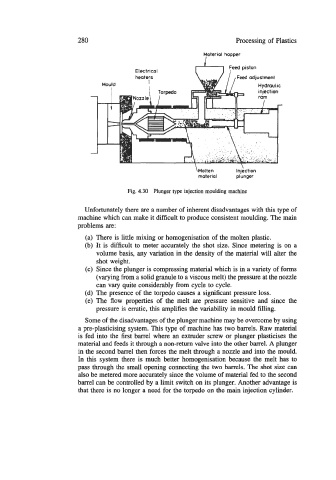

Fig. 4.30 Plunger type injection moulding machine

Unfortunately there are a number of inherent disadvantages with this type of

machine which can make it difficult to produce consistent moulding. The main

problems are:

There is little mixing or homogenisation of the molten plastic.

It is difficult to meter accurately the shot size. Since metering is on a

volume basis, any variation in the density of the material will alter the

shot weight.

Since the plunger is compressing material which is in a variety of forms

(varying from a solid granule to a viscous melt) the pressure at the nozzle

can vary quite considerably from cycle to cycle.

The presence of the torpedo causes a significant pressure loss.

The flow properties of the melt are pressure sensitive and since the

pressure is erratic, this amplifies the variability in mould filling.

Some of the disadvantages of the plunger machine may be overcome by using

a pre-plasticising system. This type of machine has two barrels. Raw material

is fed into the first barrel where an extruder screw or plunger plasticises the

material and feeds it through a non-return valve into the other barrel. A plunger

in the second barrel then forces the melt through a nozzle and into the mould.

In this system there is much better homogenisation because the melt has to

pass through the small opening connecting the two barrels. The shot size can

also be metered more accurately since the volume of material fed to the second

barrel can be controlled by a limit switch on its plunger. Another advantage is

that there is no longer a need for the torpedo on the main injection cylinder.