Page 301 - Plastics Engineering

P. 301

284 Processing of Plastics

heater band before entering the relatively cold channels in the mould. Contact

with the mould causes heat transfer from the nozzle and in cases where this

is excessive it is advisable to withdraw the nozzle from the mould during the

screw-back part of the moulding cycle. Otherwise the plastic may freeze off in

the nozzle.

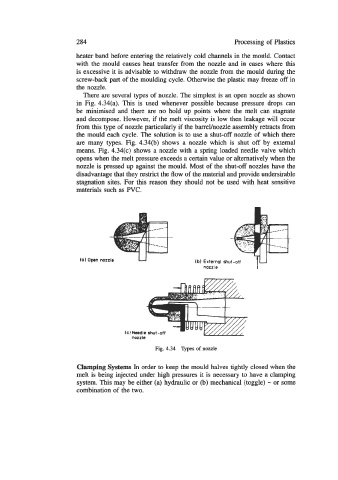

There are several types of nozzle. The simplest is an open nozzle as shown

in Fig. 4.34(a). This is used whenever possible because pressure drops can

be minimised and there are no hold up points where the melt can stagnate

and decompose. However, if the melt viscosity is low then leakage will occur

from this type of nozzle particularly if the barrelhozzle assembly retracts from

the mould each cycle. The solution is to use a shut-off nozzle of which there

are many types. Fig. 4.34(b) shows a nozzle which is shut off by external

means. Fig. 4.34(c) shows a nozzle with a spring loaded needle valve which

opens when the melt pressure exceeds a certain value or alternatively when the

nozzle is pressed up against the mould. Most of the shut-off nozzles have the

disadvantage that they restrict the flow of the material and provide undersirable

stagnation sites. For this reason they should not be used with heat sensitive

materials such as PVC.

(b) External shut-off

nozzle

IC) Needle

nozzle

Fig. 4.34 bpes of nozzle

Clamping Systems In order to keep the mould halves tightly closed when the

melt is being injected under high pressures it is necessary to have a clamping

system. This may be either (a) hydraulic or (b) mechanical (toggle) - or some

combination of the two.