Page 303 - Plastics Engineering

P. 303

286 Processing of Plastics

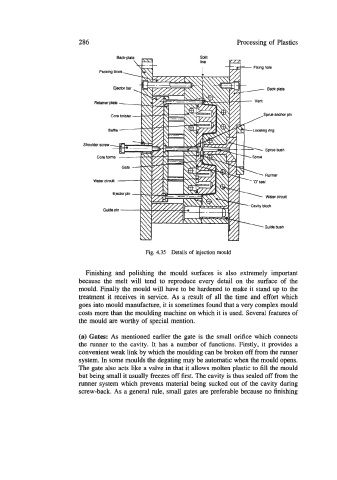

Fig. 4.35 Details of injection mould

Finishing and polishing the mould surfaces is also extremely important

because the melt will tend to reproduce every detail on the surface of the

mould. Finally the mould will have to be hardened to make it stand up to the

treatment it receives in service. As a result of all the time and effort which

goes into mould manufacture, it is sometimes found that a very complex mould

costs more than the moulding machine on which it is used. Several features of

the mould are worthy of special mention.

(a) Gates: As mentioned earlier the gate is the small orifice which connects

the runner to the cavity. It has a number of functions. Firstly, it provides a

convenient weak link by which the moulding can be broken off from the runner

system. In some moulds the degating may be automatic when the mould opens.

The gate also acts like a valve in that it allows molten plastic to fill the mould

but being small it usually freezes off first. The cavity is thus sealed off from the

runner system which prevents material being sucked out of the cavity during

screw-back. As a general rule, small gates are preferable because no finishing