Page 308 - Plastics Engineering

P. 308

Processing of Plastics 29 1

Eject 01

pins

Split Spltt

I me line

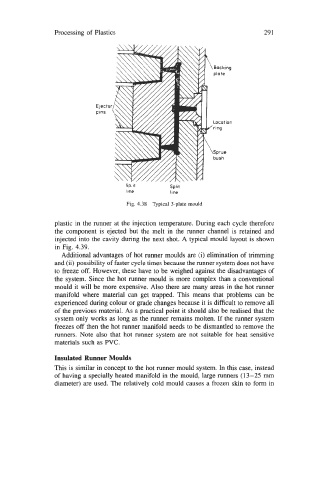

Fig. 4.38 Typical 3-plate mould

plastic in the runner at the injection temperature. During each cycle therefore

the component is ejected but the melt in the runner channel is retained and

injected into the cavity during the next shot. A typical mould layout is shown

in Fig. 4.39.

Additional advantages of hot runner moulds are (i) elimination of trimming

and (ii) possibility of faster cycle times because the runner system does not have

to freeze off. However, these have to be weighed against the disadvantages of

the system. Since the hot runner mould is more complex than a conventional

mould it will be more expensive. Also there are many areas in the hot runner

manifold where material can get trapped. This means that problems can be

experienced during colour or grade changes because it is difficult to remove all

of the previous material. As a practical point it should also be realised that the

system only works as long as the runner remains molten. If the runner system

freezes off then the hot runner manifold needs to be dismantled to remove the

runners. Note also that hot runner system are not suitable for heat sensitive

materials such as PVC.

Insulated Runner Moulds

This is similar in concept to the hot runner mould system. In this case, instead

of having a specially heated manifold in the mould, large runners (1 3 -25 mm

diameter) are used. The relatively cold mould causes a frozen skin to form in