Page 309 - Plastics Engineering

P. 309

292 Processing of Plastics

runner

channels

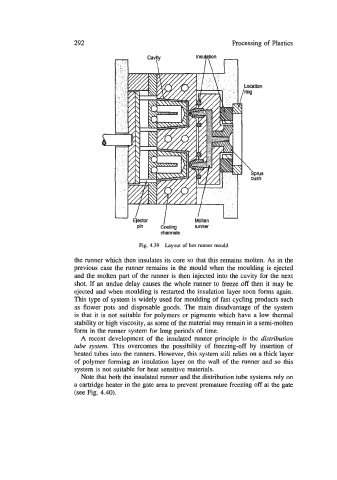

Fig. 4.39 Layout of hot runner mould

the runner which then insulates its core so that this remains molten. As in the

previous case the runner remains in the mould when the moulding is ejected

and the molten part of the runner is then injected into the cavity for the next

shot. If an undue delay causes the whole runner to freeze off then it may be

ejected and when moulding is restarted the insulation layer soon forms again.

This type of system is widely used for moulding of fast cycling products such

as flower pots and disposable goods. The main disadvantage of the system

is that it is not suitable for polymers or pigments which have a low thermal

stability or high viscosity, as some of the material may remain in a semi-molten

form in the runner system for long periods of time.

A recent development of the insulated runner principle is the distribution

tube system. This overcomes the possibility of freezing-off by insertion of

heated tubes into the runners. However, this system still relies on a thick layer

of polymer forming an insulation layer on the wall of the runner and so this

system is not suitable for heat sensitive materials.

Note that both the insulated runner and the distribution tube systems rely on

a cartridge heater in the gate area to prevent premature freezing off at the gate

(see Fig. 4.40).