Page 314 - Plastics Engineering

P. 314

Processing of Plastics 297

F = TPoL (-)

m

i.e. (4.27)

m+l

The calculation of clamp force is considered in more detail in Chapter 5.

4.3.4 Structural Foam Injection Moulding

Foamed thermoplastic articles have a cellular core with a relatively dense (solid)

skin. The foam effect is achieved by the dispersion of inert gas throughout the

molten resin directly before moulding. Introduction of the gas is usually carried

out either by pre-blending the resin with a chemical blowing agent which

releases gas when heated or by direct injection of the gas (usually nitrogen).

When the compressed gashesin mixture is rapidly injected into the mould

cavity, the gas expands explosively and forces the material into all parts of

the mould.

The advantages of these types of foam moulding are

(a) for a given weight they are many times more rigid than a solid moulding

(b) they are almost completely free from orientation effects and the shrinkage

is uniform

(c) very thick sections can be moulded without sink marks.

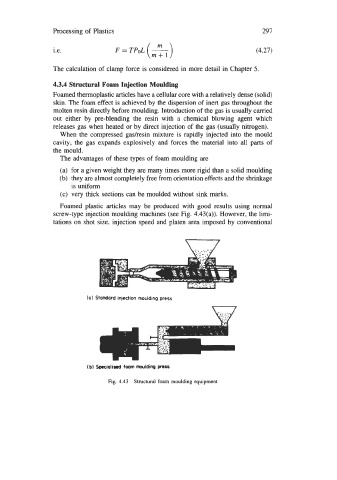

Foamed plastic articles may be produced with good results using normal

screw-type injection moulding machines (see Fig. 4.43(a)). However, the limi-

tations on shot size, injection speed and platen area imposed by conventional

; ... T-7 . ... .

'. ...:.a

(01 Stondord injection moulding press

Fig. 4.43 Structural foam moulding equipment