Page 315 - Plastics Engineering

P. 315

298 Processing of Plastics

injection equipment prevent the full large-part capabilities of structural foam

from being realised. Specialised foam moulding machines currently in use can

produce parts weighing in excess of 50 kg (see Fig. 4.43(b)).

Wall sections in foam moulding are thicker than in solid material. Longer

cycle times can therefore be expected due to both the wall thickness and the

low thermal conductivity of the cellular material. In contrast, however, the

injection pressures in foam moulding are low when compared with conventional

injection moulding. This means that less clamping force is needed per unit area

of moulding and mould costs are less because lower strength mould materials

may be used.

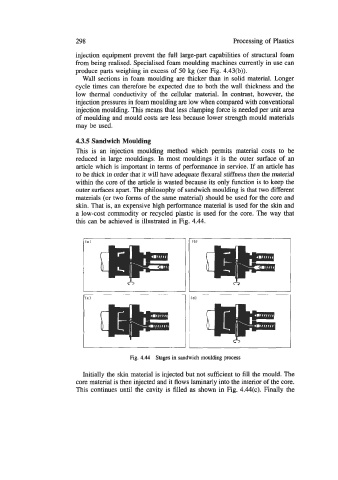

4.3.5 Sandwich Moulding

This is an injection moulding method which permits material costs to be

reduced in large mouldings. In most mouldings it is the outer surface of an

article which is important in terms of performance in service. If an article has

to be thick in order that it will have adequate flexural stiffness then the material

within the core of the article is wasted because its only function is to keep the

outer surfaces apart. The philosophy of sandwich moulding is that two different

materials (or two forms of the same material) should be used for the core and

skin. That is, an expensive high performance material is used for the skin and

a low-cost commodity or recycled plastic is used for the core. The way that

this can be achieved is illustrated in Fig. 4.44.

I IQI

I c.,

I II I

Fig. 4.44 Stages in sandwich moulding process

Initially the skin material is injected but not sufficient to fill the mould. The

core material is then injected and it flows laminarly into the interior of the core.

This continues until the cavity is filled as shown in Fig. 4.44(c). Finally the