Page 318 - Plastics Engineering

P. 318

Processing of Plastics 301

(caused by escaping gas bubbles in structural foam moulding) and cycle times

are lower because thinner sections are being cooled.

4.3.7 Shear Controlled Orientation in Injection Moulding (SCORIM)

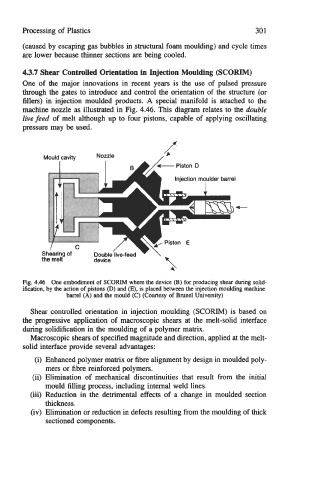

One of the major innovations in recent years is the use of pulsed pressure

through the gates to introduce and control the orientation of the structure (or

fillers) in injection moulded products. A special manifold is attached to the

machine nozzle as illustrated in Fig. 4.46. This diagram relates to the double

livefeed of melt although up to four pistons, capable of applying oscillating

pressure may be used.

Mould cavity Nozzle /

/- Piston D

Injection moulder barrel

7

A

f

Piston E

/

s ring of Do Nuble live-feed

the melt del vice \

Fig. 4.46 One embodiment of SCORIM where the device (B) for producing shear during solid-

ification, by the action of pistons @) and (E), is placed between the injection moulding machine

barrel (A) and the mould (C) (Courtesy of Brunei University)

Shear controlled orientation in injection moulding (SCORIM) is based on

the progressive application of macroscopic shears at the melt-solid interface

during solidification in the moulding of a polymer matrix.

Macroscopic shears of specified magnitude and direction, applied at the melt-

solid interface provide several advantages:

(i) Enhanced polymer matrix or fibre alignment by design in moulded poly-

mers or fibre reinforced polymers.

(ii) Elimination of mechanical discontinuities that result from the initial

mould filling process, including internal weld lines.

(iii) Reduction in the detrimental effects of a change in moulded section

thickness.

(iv) Elimination or reduction in defects resulting from the moulding of thick

sectioned components.