Page 319 - Plastics Engineering

P. 319

302 Processing of Plastics

43.8 Reaction Injection Moulding

Although there have been for many years a number of moulding methods

(such as hand lay-up of glass fibres in polyester and compression moulding

of thermosets or rubber) in which the plastic material is manufactured at the

same time as it is being shaped into the final article, it is only recently that this

concept has been applied in an injection moulding type process. In Reaction

Injection Moulding (RIM), liquid reactants are brought together just prior to

being injected into the mould. In-mould polymerisation then takes place which

forms the plastic at the same time as the moulding is being produced. In some

cases reinforcing fillers are incorporated in one of the reactants and this is

referred to as Reinforced Reaction Injection Moulding (RRIM)

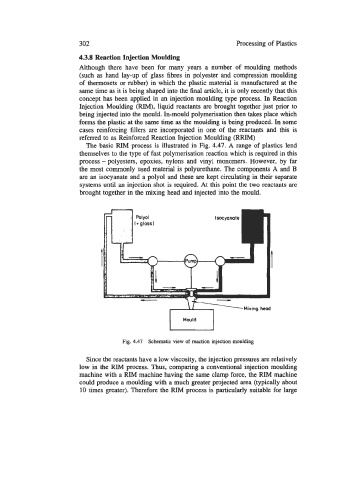

The basic RIM process is illustrated in Fig. 4.47. A range of plastics lend

themselves to the type of fast polymerisation reaction which is required in this

process - polyesters, epoxies, nylons and vinyl monomers. However, by far

the most commonly used material is polyurethane. The components A and B

are an isocyanate and a poly01 and these are kept circulating in their separate

systems until an injection shot is required. At this point the two reactants are

brought together in the mixing head and injected into the mould.

Fig. 4.47 Schematic view of reaction injection moulding

Since the reactants have a low viscosity, the injection pressures are relatively

low in the RIM process. Thus, comparing a conventional injection moulding

machine with a RIM machine having the same clamp force, the RIM machine

could produce a moulding with a much greater projected area (typically about

10 times greater). Therefore the RIM process is particularly suitable for large