Page 320 - Plastics Engineering

P. 320

Processing of Plastics 303

area mouldings such as car bumpers and body panels. Another consequence

of the low injection pressures is that mould materials other than steel may

be considered. Aluminium has been used successfully and this permits weight

savings in large moulds. Moulds are also less expensive than injection moulds

but they must not be regarded as cheap. RIM moulds require careful design

and, in particular, a good surface finish because the expansion of the material

in the mould during polymerisation causes every detail on the surface of the

mould to be reproduced on the moulding.

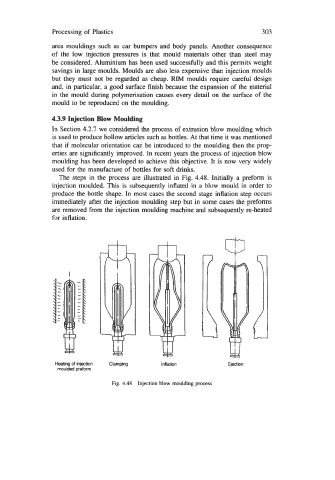

4.3.9 Injection Blow Moulding

In Section 4.2.7 we considered the process of extrusion blow moulding which

is used to produce hollow articles such as bottles. At that time it was mentioned

that if molecular orientation can be introduced to the moulding then the prop-

erties are significantly improved. In recent years the process of injection blow

moulding has been developed to achieve this objective. It is now very widely

used for the manufacture of bottles for soft drinks.

The steps in the process are illustrated in Fig. 4.48. Initially a preform is

injection moulded. This is subsequently inflated in a blow mould in order to

produce the bottle shape. In most cases the second stage inflation step occurs

immediately after the injection moulding step but in some cases the preforms

are removed from the injection moulding machine and subsequently re-heated

for inflation.

.i

I

Heating of injection Clamping Inflation Ejection

moulded preform

Fig. 4.48 Injection blow moulding process