Page 325 - Plastics Engineering

P. 325

308 pn>cessing of Plastics

is easily shaped, has good thermal conductivity, can be highly polished and

has an almost unlimited life.

Materials which can be vacuum formed satisfactorily include polystyrene,

ABS, PVC, acrylic, polycarbonate, polypropylene and high and low density

polyethylene. Co-extruded sheets of different plastics and multi-colour lami-

nates are also widely used nowadays. One of the most recent developments is

the thennoforming of crystallisable PET for high temperature applications such

as oven trays. The PET sheet is manufactured in the amorphous form and then

during thennoforming it is permitted to crystallise. The resulting moulding is

thus capable of remaining stiff at elevated temperatures.

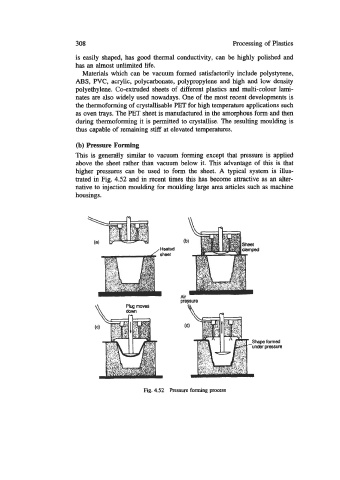

(b) Pressure Forming

This is generally similar to vacuum forming except that pressure is applied

above the sheet rather than vacuum below it. This advantage of this is that

higher pressures can be used to form the sheet. A typical system is illus-

trated in Fig. 4.52 and in recent times this has become attractive as an alter-

native to injection moulding for moulding large area articles such as machine

housings.

* ...

Plug moves

Fig. 4.52