Page 321 - Plastics Engineering

P. 321

304 Processing of Plastics

The advantages of injection blow moulding are that

(i) the injection moulded parison may have a carefully controlled wall

thickness profile to ensure a uniform wall thickness in the inflated bottle.

(ii) it is possible to have intricate detail in the bottle neck.

(iii) there is no trimming or flash (compare with extrusion blow moulding).

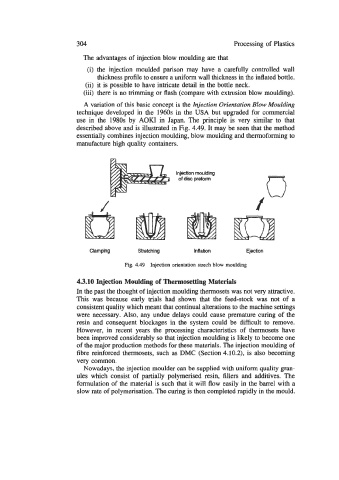

A variation of this basic concept is the Injection Orientation Blow Moulding

technique developed in the 1960s in the USA but upgraded for commercial

use in the 1980s by AOKI in Japan. The principle is very similar to that

described above and is illustrated in Fig. 4.49. It may be seen that the method

essentially combines injection moulding, blow moulding and thermoforming to

manufacture high quality containers.

Injection moulding

of disc preform U

f

Clamping Stretching Inflation Ejection

Fig. 4.49 Injection orientation strech blow moulding

4.3.10 Injection Moulding of Thermosetting Materials

In the past the thought of injection moulding thermosets was not very attractive.

This was because early trials had shown that the feed-stock was not of a

consistent quality which meant that continual alterations to the machine settings

were necessary. Also, any undue delays could cause premature curing of the

resin and consequent blockages in the system could be difficult to remove.

However, in recent years the processing characteristics of thermosets have

been improved considerably so that injection moulding is likely to become one

of the major production methods for these materials. The injection moulding of

fibre reinforced thennosets, such as DMC (Section 4.10.2), is also becoming

very common.

Nowadays, the injection moulder can be supplied with uniform quality gran-

ules which consist of partially polymerised resin, fillers and additives. The

formulation of the material is such that it will flow easily in the barrel with a

slow rate of polymerisation. The curing is then completed rapidly in the mould.