Page 324 - Plastics Engineering

P. 324

Processing of Plastics 307

Heater Plastic sheet

Vents

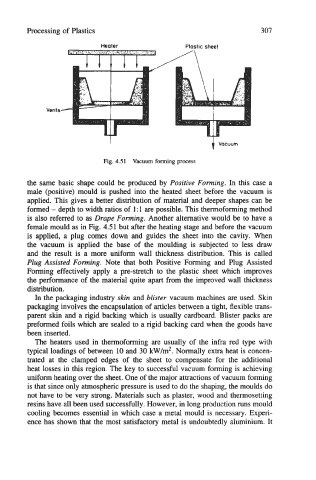

Fig. 4.51 Vacuum forming process

the same basic shape could be produced by Positive Forming. In this case a

male (positive) mould is pushed into the heated sheet before the vacuum is

applied. This gives a better distribution of material and deeper shapes can be

formed - depth to width ratios of 1 : 1 are possible. This thermoforming method

is also referred to as Drupe Forming. Another alternative would be to have a

female mould as in Fig. 4.5 1 but after the heating stage and before the vacuum

is applied, a plug comes down and guides the sheet into the cavity. When

the vacuum is applied the base of the moulding is subjected to less draw

and the result is a more uniform wall thickness distribution. This is called

Plug Assisted Forming. Note that both Positive Forming and Plug Assisted

Forming effectively apply a pre-stretch to the plastic sheet which improves

the performance of the material quite apart from the improved wall thickness

distribution.

In the packaging industry skin and blister vacuum machines are used. Skin

packaging involves the encapsulation of articles between a tight, flexible trans-

parent skin and a rigid backing which is usually cardboard. Blister packs are

preformed foils which are sealed to a rigid backing card when the goods have

been inserted.

The heaters used in thermoforming are usually of the infra red type with

typical loadings of between 10 and 30 kW/m2. Normally extra heat is concen-

trated at the clamped edges of the sheet to compensate for the additional

heat losses in this region. The key to successful vacuum forming is achieving

uniform heating over the sheet. One of the major attractions of vacuum forming

is that since only atmospheric pressure is used to do the shaping, the moulds do

not have to be very strong. Materials such as plaster, wood and thermosetting

resins have all been used successfully. However, in long production runs mould

cooling becomes essential in which case a metal mould is necessary. Experi-

ence has shown that the most satisfactory metal is undoubtedly aluminium. It