Page 323 - Plastics Engineering

P. 323

306 Processing of Plastics

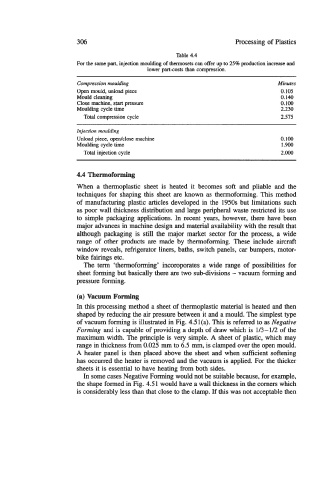

Table 4.4

For the same part, injection moulding of thermosets can offer up to 25% production increase and

lower part-costs than compression.

Compression moulding Minutes

Open mould, unload piece 0.105

Mould cleaning 0.140

Close machine, start pressure 0.100

Moulding cycle time 2.230

Total compression cycle 2.575

Injection moulding

Unload piece, opedclose machine 0.100

Moulding cycle time 1 .goo

Total injection cycle 2.000

4.4 Thennoforming

When a thermoplastic sheet is heated it becomes soft and pliable and the

techniques for shaping this sheet are known as thermoforming. This method

of manufacturing plastic articles developed in the 1950s but limitations such

as poor wall thickness distribution and large peripheral waste restricted its use

to simple packaging applications. In recent years, however, there have been

major advances in machine design and material availability with the result that

although packaging is still the major market sector for the process, a wide

range of other products are made by thermoforming. These include aircraft

window reveals, refrigerator liners, baths, switch panels, car bumpers, motor-

bike fairings etc.

The term ‘thermoforming’ incoroporates a wide range of possibilities for

sheet forming but basically there are two sub-divisions - vacuum forming and

pressure forming.

(a) Vacuum Forming

In this processing method a sheet of thermoplastic material is heated and then

shaped by reducing the air pressure between it and a mould. The simplest type

of vacuum forming is illustrated in Fig. 4.5 l(a). This is referred to as Negative

Forming and is capable of providing a depth of draw which is 113-112 of the

maximum width. The principle is very simple. A sheet of plastic, which may

range in thickness from 0.025 mm to 6.5 mm, is clamped over the open mould.

A heater panel is then placed above the sheet and when sufficient softening

has occurred the heater is removed and the vacuum is applied. For the thicker

sheets it is essential to have heating from both sides.

In some cases Negative Forming would not be suitable because, for example,

the shape formed in Fig. 4.5 1 would have a wall thickness in the comers which

is considerably less than that close to the clamp. If this was not acceptable then