Page 322 - Plastics Engineering

P. 322

Processing of Plastics 305

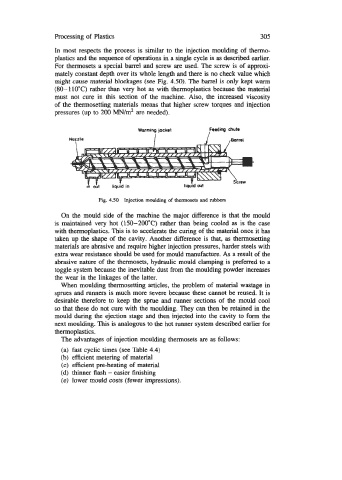

In most respects the process is similar to the injection moulding of thermo-

plastics and the sequence of operations in a single cycle is as described earlier.

For thermosets a special barrel and screw are used. The screw is of approxi-

mately constant depth over its whole length and there is no check value which

might cause material blockages (see Fig. 4.50). The barrel is only kept warm

(80-110°C) rather than very hot as with thermoplastics because the material

must not cure in this section of the machine. Also, the increased viscosity

of the thermosetting materials means that higher screw torques and injection

pressures (up to 200 MN/m2 are needed).

Warming jacket

Nafzle I

Fig. 4.50 Injection modding of thermosets and rubbers

On the mould side of the machine the major difference is that the mould

is maintained very hot (150-200°C) rather than being cooled as is the case

with thermoplastics. This is to accelerate the curing of the material once it has

taken up the shape of the cavity. Another difference is that, as thermosetting

materials are abrasive and require higher injection pressures, harder steels with

extra wear resistance should be used for mould manufacture. As a result of the

abrasive nature of the thermosets, hydraulic mould clamping is preferred to a

toggle system because the inevitable dust from the moulding powder increases

the wear in the linkages of the latter.

When moulding thermosetting articles, the problem of material wastage in

sprues and runners is much more severe because these cannot be reused. It is

desirable therefore to keep the sprue and runner sections of the mould cool

so that these do not cure with the moulding. They can then be retained in the

mould during the ejection stage and then injected into the cavity to form the

next moulding. This is analogous to the hot runner system described earlier for

thermoplastics.

The advantages of injection moulding thermosets are as follows:

(a) fast cyclic times (see Table 4.4)

(b) efficient metering of material

(c) efficient pre-heating of material

(d) thinner flash - easier finishing

(e) lower mould costs (fewer impressions).