Page 289 - Plastics Engineering

P. 289

272 Processing of Plastics

The maximum stress in the inflated parison will be the hoop stress, 00, which

is given by

PO, 0.4~

50

oo=-- -

2h 2 x 2.42

= 4.13 MN/m2

Since this is less than the melt fracture stress (6 MN/m2) these production

conditions would be suitable. These are more worked examples on extrusion

blow moulding towards the end of Chapter 5.

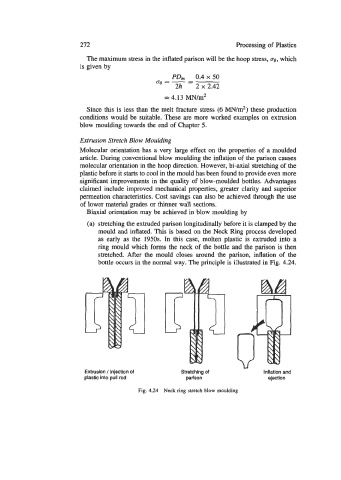

Extrusion Stretch Blow Moulding

Molecular orientation has a very large effect on the properties of a moulded

article. During conventional blow moulding the inflation of the parison causes

molecular orientation in the hoop direction. However, bi-axial stretching of the

plastic before it starts to cool in the mould has been found to provide even more

significant improvements in the quality of blow-moulded bottles. Advantages

claimed include improved mechanical properties, greater clarity and superior

permeation characteristics. Cost savings can also be achieved through the use

of lower material grades or thinner wall sections.

Biaxial orientation may be achieved in blow moulding by

(a) stretching the extruded parison longitudinally before it is clamped by the

mould and inflated. This is based on the Neck Ring process developed

as early as the 1950s. In this case, molten plastic is extruded into a

ring mould which forms the neck of the bottle and the parison is then

stretched. After the mould closes around the parison, inflation of the

bottle occurs in the normal way. The principle is illustrated in Fig. 4.24.

U

Extrusion / Injection of Stretching of Inflation and

plastic into pull rod parison ejection

Fig. 4.24 Neck ring stretch blow moulding