Page 282 - Plastics Engineering

P. 282

Processing of Plastics 265

Feedstock

Cutter haul - ,Laces,

Water bath

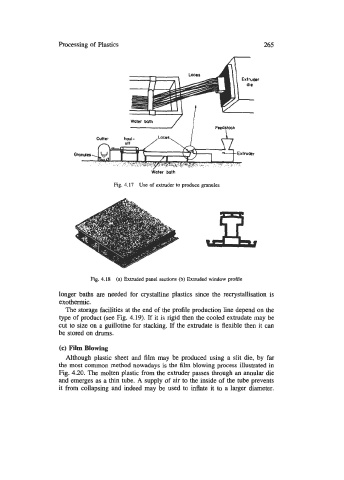

Fig. 4.17 Use of extruder to produce granules

Fig. 4.18 (a) Extruded panel sections (b) Extruded window profile

longer baths are needed for crystalline plastics since the recrystallisation is

exothermic.

The storage facilities at the end of the profile production line depend on the

type of product (see Fig. 4.19). If it is rigid then the cooled extrudate may be

cut to size on a guillotine for stacking. If the extrudate is flexible then it can

be stored on drums.

(c) Film Blowing

Although plastic sheet and film may be produced using a slit die, by far

the most common method nowadays is the film blowing process illustrated in

Fig. 4.20. The molten plastic from the extruder passes through an annular die

and emerges as a thin tube. A supply of air to the inside of the tube prevents

it from collapsing and indeed may be used to inflate it to a larger diameter.