Page 71 - Plastics Engineering

P. 71

54 Mechanical Behaviour of Plastics

examples. When using this pseudo-elastic design approach it should be remem-

bered that the creep curves used to derive modulus values have normally been

obtained on test pieces which are essentially isotropic. In practice the manu-

facture of the end-product by injection moulding or extrusion, etc. will have

resulted in some degree of anisotropy. This may make the predictions inaccu-

rate because the creep data for the material is no longer appropriate for the

structural morphology introduced by the moulding method. Similar comments

could, of course, also be made about metals in that the test data may have

been obtained on specimens of the material which do not accurately reflect the

nature of the material in the end-product. Therefore, pseudo-elastic design is a

valid analytical procedure but one should always be cautious about the way in

which the manufacturing method has affected the behaviour of the material.

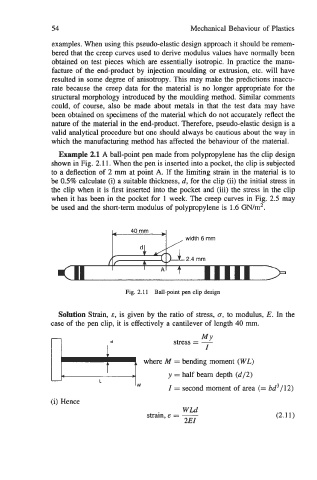

Example 2.1 A ball-point pen made from polypropylene has the clip design

shown in Fig. 2.1 1. When the pen is inserted into a pocket, the clip is subjected

to a deflection of 2 mm at point A. If the limiting strain in the material is to

be 0.5% calculate (i) a suitable thickness, d, for the clip (ii) the initial stress in

the clip when it is first inserted into the pocket and (iii) the stress in the clip

when it has been in the pocket for 1 week. The creep curves in Fig. 2.5 may

be used and the short-term modulus of polypropylene is 1.6 GN/m2.

?--+I , mm

6

width

Fig. 2.1 1 Ball-point pen clip design

Solution Strain, E, is given by the ratio of stress, u, to modulus, E. In the

case of the pen clip, it is effectively a cantilever of length 40 mm.

bw

MY

stress = -

I

where M = bending moment (WL)

y = half beam depth (d/2)

(i) Hence I = second moment of area (= bd3/12)

WLd

strain, E = - (2.11)

2EI