Page 214 - Power Quality in Electrical Systems

P. 214

196 Chapter Thirteen

■ NFPA 110-2002, “Standards for Emergency and Standby Power

Systems” [13.3]

■ NFPA 70-2005, “ National Electrical Code” specifically [13.4]

■ Art. 700, “Emergency Systems”

■ Art. 701, “Legally Required Standby Power Systems”

■ Art. 702, “Optional Standby Power Systems”

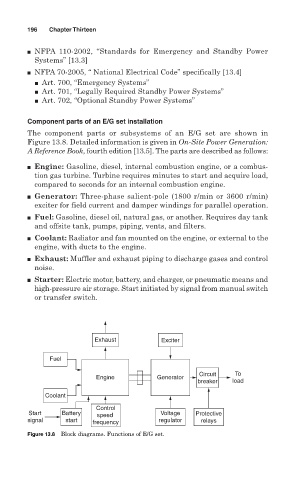

Component parts of an E/G set installation

The component parts or subsystems of an E/G set are shown in

Figure 13.8. Detailed information is given in On-Site Power Generation:

A Reference Book, fourth edition [13.5]. The parts are described as follows:

■ Engine: Gasoline, diesel, internal combustion engine, or a combus-

tion gas turbine. Turbine requires minutes to start and acquire load,

compared to seconds for an internal combustion engine.

■ Generator: Three-phase salient-pole (1800 r/min or 3600 r/min)

exciter for field current and damper windings for parallel operation.

■ Fuel: Gasoline, diesel oil, natural gas, or another. Requires day tank

and offsite tank, pumps, piping, vents, and filters.

■ Coolant: Radiator and fan mounted on the engine, or external to the

engine, with ducts to the engine.

■ Exhaust: Muffler and exhaust piping to discharge gases and control

noise.

■ Starter: Electric motor, battery, and charger, or pneumatic means and

high-pressure air storage. Start initiated by signal from manual switch

or transfer switch.

Exhaust Exciter

Fuel

Circuit To

Engine Generator

breaker load

Coolant

Control

Start Battery speed Voltage Protective

signal start frequency regulator relays

Figure 13.8 Block diagrams. Functions of E/G set.