Page 36 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 36

Qualitative Concepts in Control Engineering 11

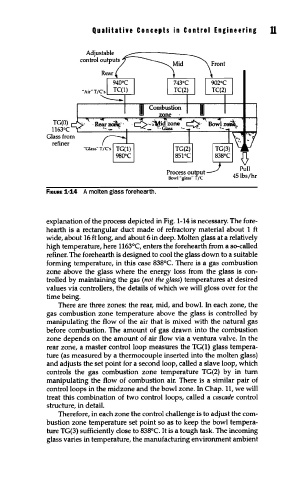

FtouRE 1-14 A molten glass forehearth.

explanation of the process depicted in Fig. 1-14 is necessary. The fore-

hearth is a rectangular duct made of refractory material about 1 ft

wide, about 16ft long, and about 6 in deep. Molten glass at a relatively

high temperature, here 1163°C, enters the forehearth from a so-called

refiner. The forehearth is designed to cool the glass down to a suitable

forming temperature, in this case 838°C. There is a gas combustion

zone above the glass where the energy loss from the glass is con-

trolled by maintaining the gas (not tlte glass) temperatures at desired

values via controllers, the details of which we will gloss over for the

time being.

There are three zones: the rear, mid, and bowl. In each zone, the

gas combustion zone temperature above the glass is controlled by

manipulating the flow of the air that is mixed with the natural gas

before combustion. The amount of gas drawn into the combustion

zone depends on the amount of air flow via a ventura valve. In the

rear zone, a master control loop measures the TG(l) glass tempera-

ture (as measured by a thermocouple inserted into the molten glass)

and adjusts the set point for a second loop, called a slave loop, which

controls the gas combustion zone temperature TG(2) by in tum

manipulating the flow of combustion air. There is a similar pair of

control loops in the midzone and the bowl zone. In Chap. 11, we will

treat this combination of two control loops, called a cascade control

structure, in detail.

Therefore, in each zone the control challenge is to adjust the com-

bustion zone temperature set point so as to keep the bowl tempera-

ture TG(3) sufficiently close to 838°C. It is a tough task. The incoming

glass varies in temperature, the manufacturing environment ambient