Page 32 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 32

Qualitative Concepts in Control Engineering 7

0.5 .-----.--....---....----.-----.-----.-----:-----.---r----.----,

0.4

0.3

0.2

Qj 0.1

~

~ 0

~ -0.1

-0.2

-0.3

-0.4

-0.5~~5 7 0--~~~~~~~~~~~~~~~~500

Time

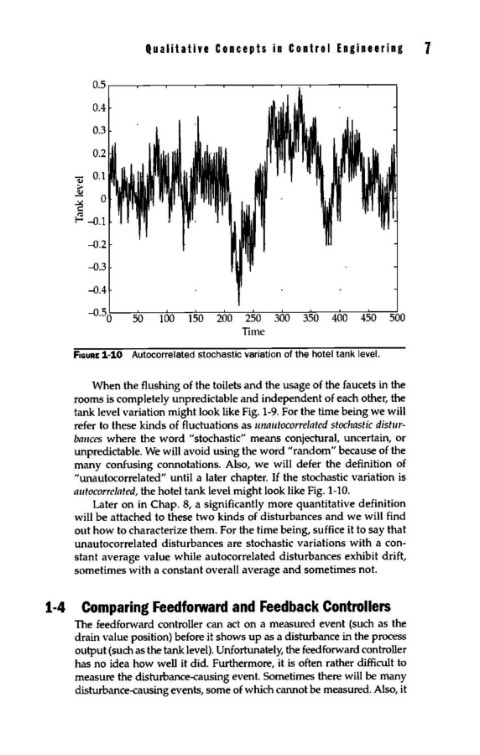

F1oURE 1-10 Autocorrelated stochastic variation of the hotel tank level.

When the flushing of the toilets and the usage of the faucets in the

rooms is completely unpredictable and independent of each other, the

tank level variation might look like Fig. 1-9. For the time being we will

refer to these kinds of fluctuations as wumtocorrelated stochastic distur-

bances where the word "stochastic" means conjectural, uncertain, or

unpredictable. We will avoid using the word "random" because of the

many confusing connotations. Also, we will defer the definition of

"unautocorrelated" until a later chapter. If the stochastic variation is

autocorre/ated, the hotel tank level might look like Fig. 1-10.

Later on in Chap. 8, a significantly more quantitative definition

will be attached to these two kinds of disturbances and we will find

out how to characterize them. For the time being, suffice it to say that

unautocorrelated disturbances are stochastic variations with a con-

stant average value while autocorrelated disturbances exhibit drift,

sometimes with a constant overall average and sometimes not.

1-4 Comparing Feedforward and Feedback Controllers

The feedforward controller can act on a measured event (such as the

drain value position) before it shows up as a disturbance in the process

output (such as the tank level). Unfortunately, the feedforward controller

has no idea how well it did. Furthermore, it is often rather difficult to

measure the disturbance-causing event. Sometimes there will be many

disturbance-causing events, some of which cannot be measured. Also, it