Page 493 - Practical Design Ships and Floating Structures

P. 493

468

state-of-the-art CFD codes are beginning to tackle complex geometries and flow conditions, recently

with the rapid increase of computer capacity and the development of numerical algorithms[2,9].

Furthermore, the usefulness and advantage in using CFD to analyze ventilation performance have

been pointed out by studies in several engineering-fields such as the building construction[l,3,4,8]

and the fire safety [5,10,11].

The purposes of this study are to understand flow and temperature characteristics in reefer container

holds and then to find how to re-design the economical ventilation system. For the sake of these

purposes, the STAR-CD, a commercial CFD code is used. However, in this paper, quantitative

information from this application is not drawn because the details of numerical methodologies used

here are not verified with systematic experiments

I.1 Backgrounds

As a typical example, Figure 1 shows the ventilation systems inside the reefer container holds. Six

ventilation units were installed, and each ventilation unit consisted of a fan and two duct columns. To

inhale the air heated by each reefer container, even at the bottom of the hold, the long ducts reached

down. However, a simple natural law, the moving-up of the heated air, was passed over in designing

this system.

In this paper, the flow and temperature characteristics between one duct and one container-column

are studied, like cascade foils. Then, based on these studies, duct system is re-designed. Finally the

performances of original and re-designed system in the three-dimensional hold are calculated and

compared.

2 NUMERICAL APPROACHES

Figure 2 shows the geometrical model of the original ventilation system for the present numerical

calculation at the design condition, when the containers are llly stored in the hold. For simplicity, it

is assumed that the half capacity of the fan is attached to each of separated duct columns and flows at

the narrow gap between containers are neglected.

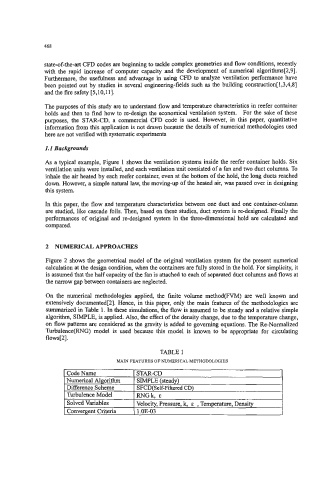

On the numerical methodologies applied, the fdte volume method(FVM) are well known and

extensively documented[2]. Hence, in this paper, only the main features of the methodologies are

summarized in Table 1. In these simulations, the flow is assumed to be steady and a relative simple

algorithm, SIMPLE, is applied. Also, the effect of the density change, due to the temperature change,

on flow patterns are considered as the gravity is added to governing equations. The Re-Normalized

Turbulence(RNG) model is used because this model is known to be appropriate for circulating

flows[ 21.

TABLE I

MAIN FEATURES OF NUMERICAL METHODOLOGIES