Page 55 - Practical Design Ships and Floating Structures

P. 55

30

rather in steady levels.

Big portions of fluctuation of prices are compulsorily absorbed by the profits of shipyards. The

advanced technologies in the present days are surely applied to the new ship building and the reduced

costs are shared by shipyards and ship owners.

The quality of ships at the delivery time is above the standard level, which is kept by the rules and the

inspections of ship classification societies. After the delivery some ship owners intend to keep their

ships for more than 20 years, the others are planning to sell their ships to get profit after using them for

a few years. Then their attitudes for the inspections and maintenance of their ships are quite different.

The former plan to increase the plate thickness above the rule scantlings and to raise the grade of

painting specification at the construction stage, anticipating the wastage or crack initiation of hull

structural members due to corrosion in service stage.

For ship owners the expenditures of ships are the summation of building cost and running costs,

including inspection, maintenance cost, insurance, fuel and personal expenses of seamen. If the

running costs are required much more than standard level on cheaper building cost, then life cycle cost

will be increased. It should be emphasized that the importance of total summation of expenses, i.e.,

life cycle cost should be understood by the management of shipping companies.

On the other hand, the shipyards can not be released from the ships which they built. Fabricators have

legally " Product Liability (PL)" on their products. Apart from this problem, shipyards must positively

recognize the meaning of life cycle cost of ships in order to utilize the limited resources of the earth.

Ln this paper the life cycle cost of a VLCC is studied. To avoid the diffusion of the problem, steel

structural members of VLCC are intentionally focussed and the life cycle cost is limited to the

summation of building cost and maintenance cost of structural part of the hull. However the idea will

be applicable to engine and outfitting parts of ships.

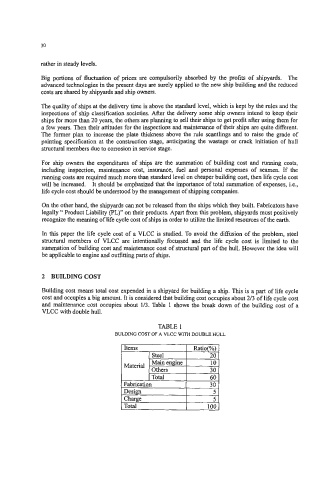

2 BUILDINGCOST

Building cost means total cost expended in a shipyard for building a ship. This is a part of life cycle

cost and occupies a big amount. It is considered that building cost occupies about 2/3 of life cycle cost

and maintenance cost occupies about 113. Table 1 shows the break down of the building cost of a

VLCC with double hull.

TABLE 1

BULDING COST OF A VLCC WITH DOUBLE HULL

Material

Others

Total

Fabrication 30

Design 5

Charge 5