Page 59 - Practical Design Ships and Floating Structures

P. 59

34

thickness reduced 30 % by corrosion in accordance with the results of inspections.

The weight of renewed steel plates of a VLCC reaches a big amount per a year, if their painting films

are not specially maintained in good condition.

4 TRADE OFF OF COST-RISK

It is a very difficult question how long the lives of ships are. They are influenced not only by technical

matters, but also by political ones. Some ship owners invest enough money to building cost, expecting

the less troubles in future and pay good attention for the maintenance of ships to keep their good

conditions. The others repeat buy and sell of ships in short cycles to get profit from the market. It is

difficult to judge their policies and to decide the best ships’ lives.

Now let’s compare which is a better way of maintenance from view point of life cycle costs of a

VLCC at 10 years and 20 years, between by an ordinary painting or by heavy duty painting.

Periodical survey is made once every 5 years and intermediate survey is made every 2 years.

The maintenance by an ordinary painting is based on the following assumptions,

(1) Number of average failures is 3 per a year until 10 years and 6 per a year after

10yearS.

(2) Steel weight of 20 tons is renewed at wasted structures due to corrosion every year after 10 years. It

is equal to 0.25% of building cost.

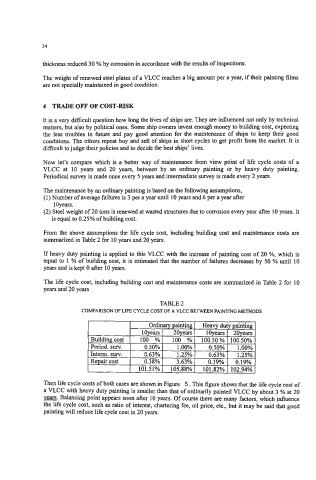

From the above assumptions the life cycle cost, including building cost and maintenance costs are

summarized in Table 2 for IO years and 20 years.

If heavy duty painting is applied to this VLCC with the increase of painting cost of 20 %, which is

equal to 1 % of building cost, it is estimated that the number of failures decreases by 50 % until 10

years and is kept 0 after 10 years.

The life cycle cost, including building cost and maintenance costs are summarized in Table 2 for 10

years and 20 years

TABLE 2

COMPARISON OF LlFE CYCLE COST OF A VLCC BETWEEN PAMTMG METHODS

Then life cycle costs of both cases are shown in Figure 5. This figure shows that the life cycle cost of

a VLCC with heavy duty painting is smaller than that of ordinarily painted VLCC by about 3 % at 20

yea~s. Balancing point appears soon after 10 years. Of come there are many factors, which influence

the life cycle cost, such as ratio of interest, chartering fee, oil price, etc., but it may be said that good

painting will reduce life cycle cost in 20 years.