Page 190 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 190

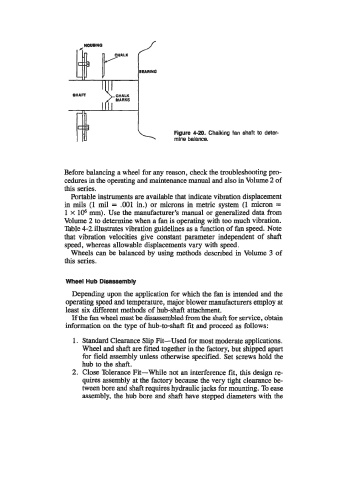

Figure 4-20. Chalking fan shaft to deter-

mine balance.

Before balancing a wheel for any reason, check the troubleshooting pro-

cedures in the operating and maintenance manual and also in Volume 2 of

this series.

Portable instruments are available that indicate vibration displacement

in mils (1 mil = .001 in.) or microns in metric system (1 micron =

1 x 106 mm). Use the manufacturer’s manual or generalized data from

Volume 2 to determine when a fan is operating with too much vibration.

nble 4-2. illustrates vibration guidelines as a hnction of fan speed. Note

that vibration velocities give constant parameter independent of shaft

speed, whereas allowable displacements vary with speed.

Wheels can be balanced by using methods described in Volume 3 of

this series.

Wheel Hub Disassembly

Depending upon the application for which the fan is intended and the

operating speed and temperature, major blower manufacturers employ at

least six different methods of hub-shaft attachment.

If the fan wheel must be disassembled from the shaft for service, obtain

information on the type of hub-to-shaft fit and proceed as follows:

1. Standard Clearance Slip Fit-Used for most moderate applications.

Wheel and shaft are fitted together in the factory, but shipped apart

for field assembly unless otherwise specified. Set screws hold the

hub to the shaft.

2. Close Tolerance Fit-While not an interference fit, this design re-

quires assembly at the factory because the very tight clearance be-

tween bore and shaft requires hydraulic jacks for mounting. To ease

assembly, the hub bore and shaft have stepped diameters with the