Page 189 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 189

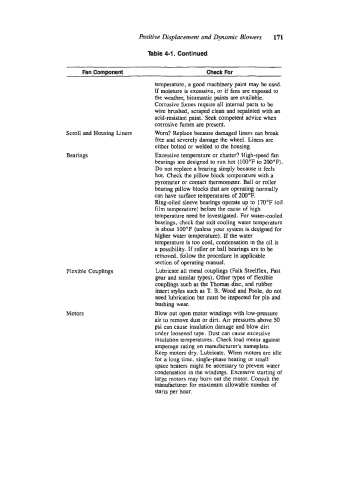

Positive Displacement and Dynamic Blowers 171

Table 4-1. Continued

Fan Component Check For

temperature, a good machinery paint may be used.

If moisture is excessive, or if fans are exposed to

the weather, bitumastic paints are available.

Corrosive fumes require all internal parts to be.

wire brushed, scraped clean and repainted with an

acid-resistant paint. Seek competent advice when

corrosive fumes are present.

Scroll and Housing Liners Worn? Replace because damaged liners can break

free and severely damage the wheel. Liners are

either bolted or welded to the housing.

Bearings Excessive temperature or chatter? High-speed fan

bearings are designed to run hot (100°F to 200°F).

Do not replace a bearing simply because it feels

hot. Check the pillow block temperature with a

pyrometer or contact thermometer. Ball or roller

bearing pillow blocks that are operating normaliy

can have surface temperatures of 200°F.

Ring-oiled sleeve bearings operate up to 170°F (oil

film temperature) before the cause of high

temperature need be investigated. For water-cooled

bearings, check that exit cooling water temperature

is about 100°F (unless your system is designed for

higher water temperature). If the water

temperature is too cool, condensation in the oil is

a possibility. If roller or ball bearings are to be

removed, follow the procedure in applicable

section of operating manual.

Rexible Couplings Lubricate all metal couplings (Fdk Steelflex, Fast

gear and similar types). Other types of flexible

couplings such as the Thomas disc, and rubber

insert styles such as T. B. Wood and hole, do not

need lubrication but must be inspected for pin and

bushing wear.

Motors Blow out open motor windings with low-pressure

air to remove dust or dirt. Air pressures above 50

psi can cause insulation damage and blow dirt

under loosened tape. Dust can cause excessive

insulation temperatures. Check load motor against

amperage rating on manufacturer’s nameplate.

Keep motors dry. Lubricate. When motors are idle

for a long time, single-phase heating or small

space heaters might be necessary to prevent water

condensation in the windings. Excessive starting of

large motors may burn out the motor. Consult the

manufacturer for maximum allowable number of

starts per hour.