Page 193 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 193

Positive Displacement and Llynamic Blowers 175

6. Use a split bushing to push the packing to the bottom of the box.

Seat the ring firmly by replacing the gland and taking up on the

bushing. Seat this bottom ring hard, because this first ring does

most of the sealing.

7. Repeat with each packing ring, making sure to stagger the joints

90" apart.

8. If a lantern ring is used, position it properly under the grease or

purge hole(s) in the box.

9. After the last ring is installed, position the gland and finger tighten

the bolts.

10. Break the packing in (refer to Volume 3 of this series).

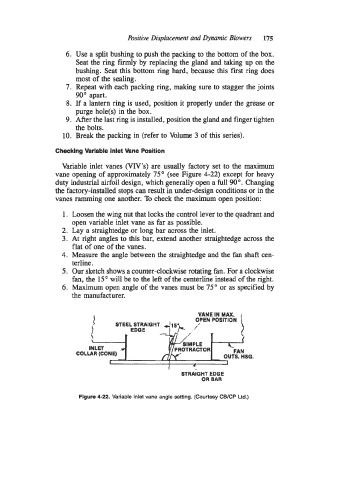

Checking hrlabie inlet Vane Poaltlon

Variable inlet vanes (VIV's) are usually factory set to the maximum

vane opening of approximately 75" (see Figure 4-22) except for heavy

duty industrial airfoil design, which generally open a full 90". Changing

the factory-installed stops can result in under-design conditions or in the

vanes ramming one another. To check the maximum open position:

1. Loosen the wing nut that locks the control lever to the quadrant and

open variable inlet vane as far as possible.

2. Lay a straightedge or long bar across the inlet.

3. At right angles to this bar, extend another straightedge across the

flat of one of the vanes.

4. Measure the angle between the straightedge and the fan shaft cen-

terline .

5. Our sketch shows a counter-clockwise rotating fan. For a clockwise

fan, the 15" will be to the left of the centerline instead of the right.

6. Maximum open angle of the vanes must be 75" or as specified by

the manufacturer.

2!

STEEL STRAIQHT 8 2!

VANE IN MAX

MAX

VANE

IN

OPEN

{ 1 1 I , OPEN POSlTlON

POSlTlON

STRAIQHT

STEEL

,

{

EDGE -I EDGE

SIMPLE

SIMPLE

INLET PROTRACTOR

PROTRACTOR

INLET

(CONE)

.LAR

COI .LAR (CONE) OUTS. HSQ.

HSQ.

OUTS.

STRAIGHT EDGE

STRAIGHT EDGE

OR BAR

OR BAR

Figure 4-22. Variable inlet vane angle setting. (Courtesy CB/CP Ltd.)