Page 209 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 209

Reciprocating Gas Engines and Compressors 191

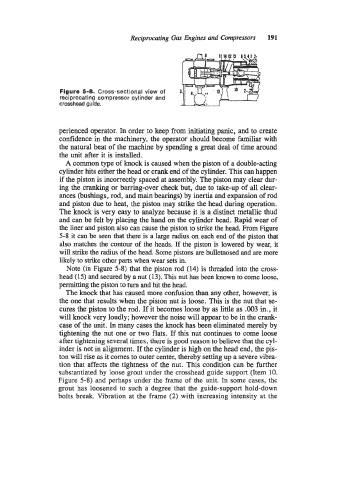

Figure 5-8. Cross-sectional view of

reciprocating compressor cylinder and

crosshead guide.

perienced operator. In order to keep from initiating panic, and to create

confidence in the machinery, the operator should become familiar with

the natural beat of the machine by spending a great deal of time around

the unit after it is installed.

A common type of hock is caused when the piston of a double-acting

cylinder hits either the head or crank end of the cylinder. This can happen

if the piston is incorrectly spaced at assembly. The piston may clear dur-

ing the cranking or barring-over check but, due to take-up of all clear-

ances (bushings, rod, and main bearings) by inertia and expansion of rod

and piston due to heat, the piston may strike the head during operation.

The knock is very easy to analyze because it is a distinct metallic thud

and can be felt by placing the hand on the cylinder head. Rapid wear of

the liner and piston also can cause the piston to strike the head. From Figure

5-8 it can be seen that there is a large radius on each end of the piston that

also matches the contour of the heads. If the piston is lowered by wear, it

will strike the radius of the head. Some pistons are bulletnosed and are more

likely to strike other parts when wear sets in.

Note (in Figure 5-8) that the piston rod (14) is threaded into the cross-

head (1 5) and secured by a nut (13). This nut has been known to come loose,

permitting the piston to turn and hit the head.

The knock that has caused more confusion than any other, however, is

the one that results when the piston nut is loose. This is the nut that se-

cures the piston to the rod. If it becomes loose by as little as .003 in., it

will knock very loudly; however the noise will appear to be in the crank-

case of the unit. In many cases the knock has been eliminated merely by

tightening the nut one or two flats. If this nut continues to come loose

after tightening several times, there is good reason to believe that the cyl-

inder is not in alignment. If the cylinder is high on the head end, the pis-

ton will rise as it comes to outer center, thereby setting up a severe vibra-

tion that affects the tightness of the nut. This condition can be further

substantiated by loose grout under the crosshead guide support (Item 10,

Figure 5-8) and perhaps under the frame of the unit. In some cases, the

grout has loosened to such a degree that the guide-support hold-down

bolts break. Vibration at the frame (2) with increasing intensity at the