Page 213 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 213

Reciprocating Gas Engines and Compressors 195

standard, and the signs tell the person analyzing the readings whether the

shaft is bowed or sagging.

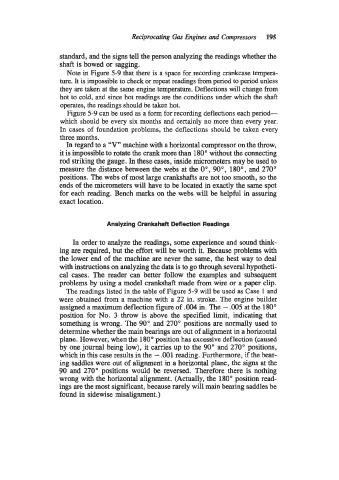

Note in Figure 5-9 that there is a space for recording crankcase tempera-

ture. It is impossible to check or repeat readings from period to period unless

they are taken at the same engine temperature. Deflections will change from

hot to cold, and since hot readings are the conditions under which the shaft

operates, the readings should be taken hot.

Figure 5-9 can be used as a form for recording deflections each period-

which should be every six months and certainly no more than every year.

In cases of foundation problems, the deflections should be taken every

three months.

In regard to a "V" machine with a horizontal compressor on the throw,

it is impossible to rotate the crank more than 180" without the connecting

rod striking the gauge. In these cases, inside micrometers may be used to

measure the distance between the webs at the 0", go", 180", and 270"

positions. The webs of most large crankshafts are not too smooth, so the

ends of the micrometers will have to be located in exactly the same spot

for each reading. Bench marks on the webs will be helpful in assuring

exact location.

Analyzing Crankshaft Deflection Readlngs

In order to analyze the readings, some experience and sound think-

ing are required, but the effort will be worth it. Because problems with

the lower end of the machine are never the same, the best way to deal

with instructions on analyzing the data is to go through several hypotheti-

cal cases. The reader can better follow the examples and subsequent

problems by using a model crankshaft made from wire or a paper clip.

The readings listed in the table of Figure 5-9 will be used as Case 1 and

were obtained from a machine with a 22 in. stroke. The engine builder

assigned a maximum deflection figure of .004 in. The - .005 at the 180"

position for No. 3 throw is above the specified limit, indicating that

something is wrong. The 90" and 270" positions are normally used to

determine whether the main bearings are out of alignment in a horizontal

plane. However, when the 180" position has excessive deflection (caused

by one journal being low), it carries up to the 90" and 270" positions,

which in this case results in the - .001 reading. Furthermore, if the bear-

ing saddles were out of alignment in a horizontal plane, the signs at the

90 and 270" positions would be reversed. Therefore there is nothing

wrong with the horizontal alignment. (Actually, the 180" position read-

ings are the most significant, because rarely will main bearing saddles be

found in sidewise misalignment.)