Page 43 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 43

28 Major Process Equipment Maintenance and Repair

RADIAL BEARING T

RADIAL BEARING

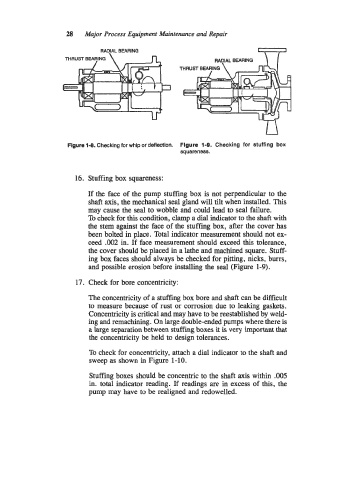

Figure 1-8. Checking for whip or deflection. Figure 1-9. Checking for stuffing box

squareness.

16. Stuffing box squareness:

If the face of the pump stuffing box is not perpendicular to the

shaft axis, the mechanical seal gland will tilt when installed. This

may cause the seal to wobble and could lead to seal failure.

To check for this condition, clamp a dial indicator to the shaft with

the stem against the face of the stuffing box, after the cover has

been bolted in place. Total indicator measurement should not ex-

ceed .002 in. If face measurement should exceed this tolerance,

the cover should be placed in a lathe and machined square. Stuff-

ing box faces should always be checked for pitting, nicks, burrs,

and possible erosion before installing the seal (Figure 1-9).

17. Check for bore concentricity:

The concentricity of a stuffing box bore and shaft can be difficult

to measure because of rust or corrosion due to leaking gaskets.

Concentricity is critical and may have to be reestablished by weld-

ing and remachining. On large double-ended pumps where there is

a large separation between stuffing boxes it is very important that

the concentricity be held to design tolerances.

To check for concentricity, attach a dial indicator to the shaft and

sweep as shown in Figure 1-10.

Stuffing boxes should be concentric to the shaft axis within .005

in. total indicator reading. If readings are in excess of this, the

pump may have to be realigned and redowelled.