Page 47 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 47

32 Major Process Equipment Maintenance and Repair

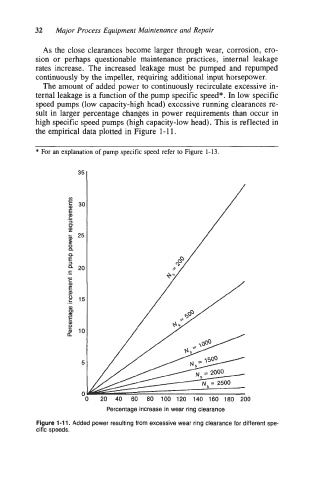

As the close clearances become larger through wear, corrosion, ero-

sion or perhaps questionable maintenance practices, internal leakage

rates increase. The increased leakage must be pumped and repumped

continuously by the impeller, requiring additional input horsepower.

The amount of added power to continuously recirculate excessive in-

ternal leakage is a function of the pump specific speed*. In low specific

speed pumps (low capacity-high head) excessive running clearances re-

sult in larger percentage changes in power requirements than occur in

high specific speed pumps (high capacity-low head). This is reflected in

the empirical data plotted in Figure 1-1 1.

* For an explanation of pump specific speed refer to Figure 1-13.

35

u)

c

30

E

P

.-

2

0-

P

& 25

3

0

n

n

5

E 20

.-

.-

C

E

P

.- 15

P)

0

m

c.

C

8

& 10

n / /

C / / /is-

/

S

0

0 20 40 60 80 100 120 140 160 180 200

Percentage increase in wear ring clearance

Figure 1-1 1. Added power resulting from excessive wear ring clearance for different spe-

cific speeds.