Page 44 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 44

Installation, Maintenance, and Repair of Horizontal Pumps 29

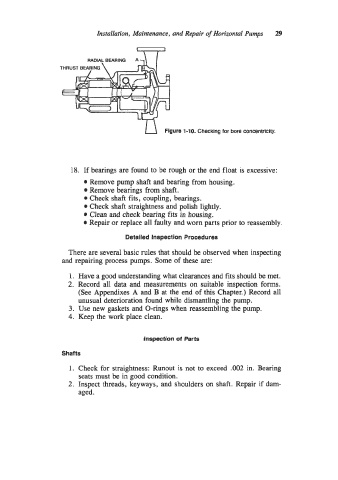

"U Figure 1-1 0. Checking for bore concentricity.

18. If bearings are found to be rough or the end float is excessive:

Remove pump shaft and bearing from housing.

Remove bearings from shaft.

Check shaft fits, coupling, bearings.

Check shaft straightness and polish lightly.

Clean and check bearing fits in housing.

Repair or replace all faulty and worn parts prior to reassembly.

Detailed Inspection Procedures

There are several basic rules that should be observed when inspecting

and repairing process pumps. Some of these are:

1. Have a good understanding what clearances and fits should be met.

2. Record all data and measurements on suitable inspection forms.

(See Appendixes A and B at the end of this Chapter.) Record all

unusual deterioration found while dismantling the pump.

3. Use new gaskets and O-rings when reassembling the pump.

4. Keep the work place clean.

Inspection of Parts

Shafts

1. Check for straightness: Runout is not to exceed .002 in. Bearing

seats must be in good condition.

2. Inspect threads, keyways, and shoulders on shaft. Repair if dam-

aged.