Page 188 - Pressure Vessel Design Manual

P. 188

166 Pressure Vessel Design Manual

PROCEDURE 3-10

DESIGN OF HORIZONTALVESSEL ON SADDLES [I, 3, 5, 14, 151

S = allowable stress, tension, psi

~

Notation S, =allowable stress, compression, psi

S1-14 = shell, head, and ring stresses, psi

A, = cross-sectional area of composite ring stiffen- K1-9 = coefficients

er, in. 2 FL = longitudinal force due to wind, seismic, expan-

Af = projected area of vessel, ft2 sion, contraction, etc., lb

E =joint efficiency FT =transverse force, wind or seismic, lb

El = modulus of elasticity, psi ax = longitudinal stress, internal pressure, psi

Ch = seismic factor (see Procedure 3-3) c+ = circumferential stress, internal pressure, psi

Cf = shapefactor = 0.8 a,, = longitudinal stress, external pressure, psi

q, =wind pressure, psf as = circumferential stress in stiffening ring, psi

De = effective vessel diameter, ft ah = latitudinal stress in head due to internal pres-

I~ = moment of inertia of ring stiffener, in.4 sure, psi

t, = thickness of wear plate, in. F, = minimum yield stress, shell, psi

t, =thickness of shell, in. P = internal pressure, psi

th =thickness of head, in. P,, = external pressure, psi

Q =total load per saddle (including piping loads, G = gust factor, wind

wind or seismic reactions, platforms, operating K, =velocity pressure coefficient

liquid, etc.) lb I =importance factor, 1.el.25 for vessels

W, = operating weight of vessel, lb V =basic wind speed, mph

MI = longitudinal bending moment at saddles, in.-lb K, = pier spring rate, 46 k.

M2 = longitudinal bending moment at midspan, ~.l. = friction coefficient

in. -1b y =pier deflection, in.

R, E mean radius, in.

R

,- = radius, ft

l' = 1.56 fi

Stiffening

ring

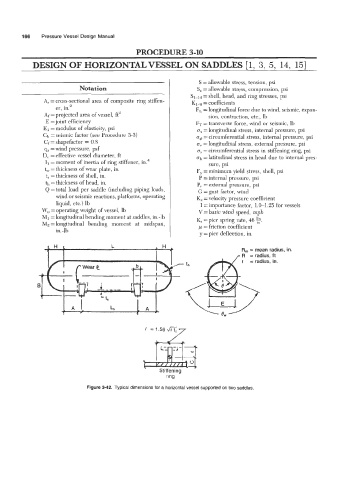

Figure 3-42. Typical dimensions for a horizontal vessel supported on two saddles.