Page 250 - Pressure Vessel Design Manual

P. 250

228 Pressure Vessel Design Manual

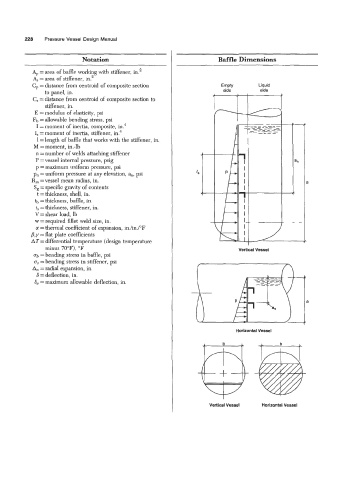

Notation Baffle Dimensions

Ap = area of baffle working with stiffener, ina2

A, = area of stiffener, in.2

C, = distance from centroid of composite section

to panel, in.

C, = distance from centroid of composite section to

stiffener, in.

E = modulus of elasticity, psi

Fb = allowable bending stress, psi

I = moment of inertia, composite, in?

I, = moment of inertia, stiffener, in.4

1 =length of baffle that works with the stiffener, in.

M =moment, in.-lb

n =number of welds attaching stiffener

P =vessel internal pressure, psig

p = maximum uniform pressure, psi

p, = uniform pressure at any elevation, a,, psi

R, =vessel mean radius, in.

S, = specific gravity of contents

t =thickness, shelI, in.

tb =thickness, baMe, in.

t, =thickness, stiffener, in.

V = shear load, Ib

w = required fillet weld size, in.

a = thermal coefficient of expansion, in./in.PF

p, y = flat plate coefficients

AT = differential temperature (design temperature

minus 70°F), OF Vertical Vessel

ab =bending stress in baffle, psi

a, =bending stress in stiffener, psi

An = radial expansion, in.

6 =deflection, in.

6, = maximum allowable deflection, in.

a

Horizontal Vessel

Vertical Vessel Horizontal Vessel