Page 47 - Pressure Vessel Design Manual

P. 47

General Design 33

0 External pressure, P,. Assume corroded head thickness, th where P = 1.5 x greater of Pi or P,. (See Reference 1,

0.125th Figure UW-13.1.)

Factor A = ____

L 0 Shear loads on welds, F.

Factor B can be taken from applicable material charts in

Section 11, Part D, Subpart 3 of Reference 1.

Alternatively (or if Factor A lies to the left of the material/

temperature line):

B=- AE I

2 Note: sin8 applies to Figure 2-5, Case 3 head at-

pe L tachments only!

t'=B

The required head thickness shall be the greater of that 0 Shear stress, 5.

required for external pressure or that required for an in-

F

ternal pressure equal to 1.67 x P,. See Reference 1, Para. t=--

UG-33(a). AS

Shear Stress 0 Allowable shear stress, SE.

0 Hydrostatic end force, HD.

PnD2

Hn=-

4

PROCEDURE 2-6

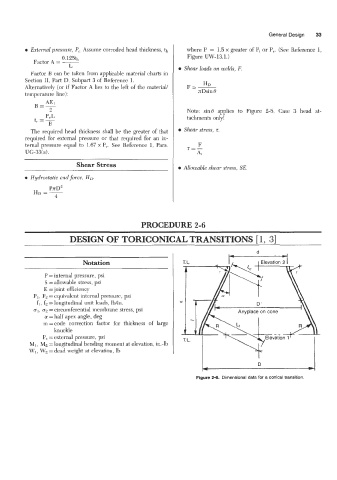

DESIGN OF TORICONICAL TRANSITIONS 11, 31

d

I I-

Notation

P = internal pressure, psi

S = allowable stress, psi

E =joint efficiency

PI, P2 = equivalent internal pressure, psi

fi, f2 = longitudinal unit loads, lb/in.

ul. uz = circumferential membrane stress, psi Anyplace on cone

a =half apex angle, deg

m=code correction factor for thickness of large

knuckle

P, =external pressure, psi

MI, M2 =longitudinal bending moment at elevation, in.-lb

WI, Wz = dead weight at elevation, lb I

D

Figure 2-6. Dimensional data for a conical transition.