Page 91 - Pressure Vessel Design Manual

P. 91

72 Pressure Vessel Design Manual

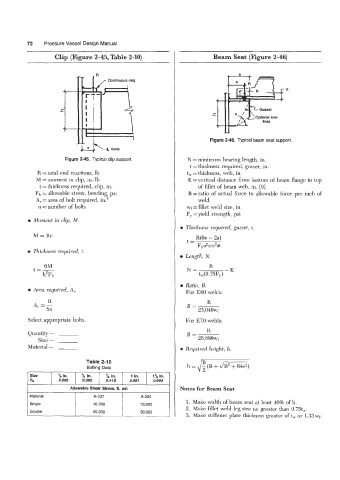

Clip (Figure 2-45, Table 2-10) Beam Seat (Figure 2-46)

I c hr I Gusset 1 K

! ;-

L

/

Optional trim

* Figure 2-46. Typical beam seat support.

-

lines

bolts

Figure 2-45. Typical clip support. N = minimum bearing length, in.

t =thickness required, gusset, in.

R =total end reactions, lb t, = thickness, web, in.

M =moment in clip, in.-lb K =vertical &stance from bottom of beam flange to top

t =thickness required, clip, in. of fillet of beam web, in. [9]

Fb = allowable stress, bending, psi B =ratio of actual force to allowable force per inch of

A, = area of bolt required, in.' weld

n = number of bolts wf= fillet weld size, in.

F, =yield strength, psi

0 Moment in clip, M.

e Thickness required, gusset, t.

M = Re R(6e - 2a)

t=

Fba2sin2#

e Thickness required, t.

e Length, N.

6M R

t=- N= -K

h2Fb tW(0.75F,)

e Ratio, B.

0 Area required, A, For E60 welds:

R

A, = g B= R

23,040wf

Select appropriate bolts. For E70 welds:

Quantity - B= R

Size - 26,880wf

Material - rn Required height, h.

Size 78 in. % in. in. 1 in. 1% in.

R. 0.202 0.302 0.41 9 0.551 0.693

I Allowable Shear Stress, S, psi I Notes €or Beam Seat

I Material I A-307 1 ~ A-3r 1

1. Make width of beam seat at least 40% of h.

Single 10,000 15,000

2. Make fillet weld leg size no greater than 0.75tW.

Double 20,000 30,000

3. Make stiffener plate thickness greater oft, or 1.33wf.