Page 278 - Pressure Swing Adsorption

P. 278

', ( .

254 PRESSURE SWING ADSORPTION PSA PROCESSES 255

modest ({3 = 0.5) and the initial moie fraction 1s .large (Yo= 0.5), the

!000

deviations from lirtearity, for both PA and f~ , are small. However, when the

3

r1-~- selectivity is high and the mJtial mole fraction of A is small, the curve for F, 1

--~ becomes essentially linear. but the curve for FA assumes a highlv nonlinear

I/min form. It is clear that, in this situation, by a sufficiently targe reduction m total

0.52 0

pressure almost all of component B can be desorbed with verv little desorn-

t.01 C, tion of A. A further deep blowdown or evacuation step then allows A to be

'~I nonlinearity 1s actually to enhance the degree of seoaration and concentra~

2.0

0.1 100 removed in concentrated form.

D

This analysis is for a linear eouilibrium system, but ·the effect of isotherm

\ 2:: 0 l t10n that can be achieved m this type of process. Since the 1soth·erm for the

more strongly adsorbed species will generally have the higher cutvature, even

~

less of this comoonent is desorbed dunng the imtial blowdown compared

with the eamvaJent linear equilihriurn svstem.

0.01 10 I. A process of this kind has rccentlv been developed as a means of

concentrating and removing the traces of tritium from the helium purge

stream of a lithium breeder reactor.-~~ To achieve a high concentration ratio

3

( ~ 10 ) requires a high select1v1ty ratio (as well as a high pressure ratio). and

for H (or tritium) this can be achieved only by qperating at cryogenic

2

yty temperatures with vacuum ctesorotion at a very low oressure. Laboratory data

~ showtng the feasibility of recovering hydrogen at greater than 90% punty and

"

with a similarity high fract10nal recovery from a stream containing traces of

0.001

0 200 400 600 800 1000 1200 H 2 m He are summarized m Figure 6.22 and Table 6.6. The process

schematic 1s shown m Figure 6.23.

Vol. of Gas lcmJ at 298 K, l atml 37 3

The same principle was used by Yang and co-workers · tt in recent studies

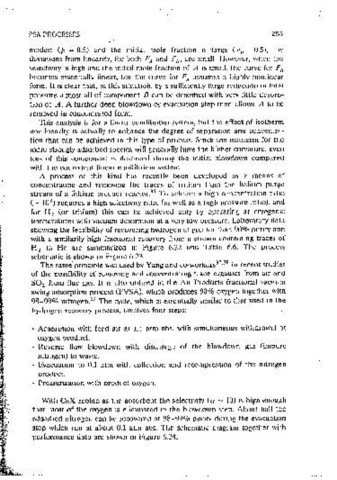

Figure 6.22 · Expenmental data showing concentration of hydrogen from a /12-He of the possibility of removmg and concentratmg trace organics from air and

mixture dunng blowctown of a small experimental column of 5A zeolite, eqmllbratect 1' SO from flue gas. It 1s also utilized in the Air' Products fractional vacuum

2

initiaflv at 77 K with a stream containmg 0.16% H 2 in He at 21.4 atm. Column swing adsorption process (FVSA), whicl1 produces 90% oxygen together with

15.6 cTTlx0.77 cm 1.d. packed with 20-40 mesh SA mol sieve particles. (From Ruthven 98-99% nltrogen. 39 The cycle, which 1s essentially similar to that used m the

and Farooq. 36 ) -

hydrogen recovery process, mvolves four steps:

• Actsorot10n with feed air at 1.1 atm abs. with simurtaneous withctrawai of

oxygen product.

36

Table 6.6. Recovery of H from the He by Cryogemc PSA " Reverse flow blowdown with discharge of the blowdown gas (impure

2

Adsorbent 5.6 g 5A zeolite (pelleted) nitrogen) to waste.

Feed 0.J8%H 2 mHeat21.4atm Evacuat10n to 0.1 atm with collection and recompression of the nitrogen

Hydrogen uptake 240cmJ STP product.

Exhaust gas 220 cmJ STP Pressunzation with product oxygen.

Puntv 93%H 2

Recoverv 85%

With CaX zeolite as the adsorbent the seiecnv1ty (a ~ 10) 1s high enough

Bed was equilibrated with feed, blown down to atmospheric pressure, and that most of the oxygen ts elimmated m the blowdown step. About half the

cvacuated to 0.01 atm. Exhaust gas was collected from vacuum pump. adsorbed nitrogen can be recovered at 98-99% ounty. dunng the evacuation

step which run at about 0.1 atm abs. The schematic diagram together with

performance data are shown m Figure 6.24.